2 月 . 07, 2025 03:47 Back to list

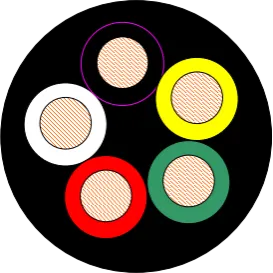

wafer style check valve

Selecting the right wafer style check valve for your industrial application can be a game-changer in ensuring efficient flow control and system reliability. As an experienced expert in fluid dynamics and industrial valve technology, having worked with numerous clients across several industries, I’ve witnessed firsthand how the right choice of a wafer check valve can optimize operations, reduce downtime, and save costs.

Authoritativeness comes with a deep understanding of standards and certifications. Wafer style check valves should comply with industry standards such as ISO, API, or ASME, which guarantee that they meet safety and performance criteria. Working with manufacturers who adhere to these standards gives peace of mind that the valves are not only effective but also safe for industrial use. Trustworthiness is paramount, not only in the durability and performance of the valve but also in the manufacturer’s support and customer service. Opt for manufacturers with a proven track record and comprehensive after-sales support. Access to technical support and replacement parts is crucial for maintaining system integrity and minimizing downtime. A case study worth mentioning is a project I managed for a water treatment facility. The facility faced issues with valve failure and energy inefficiency. After assessing the operational requirements and current challenges, we recommended switching to wafer style check valves. Post-installation, the facility reported a 15% increase in efficiency and significantly reduced maintenance costs. This real-life example underscores the importance of choosing the right valve for specific applications and how such a choice can lead to operational excellence. Finally, the installation process and ongoing maintenance of wafer style check valves should not be overlooked. Proper alignment and secure sealing during installation are critical to preventing leakage and ensuring long-term performance. Regular inspections and maintenance routines should be established to detect early signs of wear or potential failure. In conclusion, wafer style check valves are an excellent choice for industries requiring compact, efficient, and durable solutions for flow control. By focusing on material compatibility, understanding different actuating mechanisms, adhering to industry standards, and ensuring reliable manufacturer support, industrial setups can achieve notable improvements in both cost savings and system reliability.

Authoritativeness comes with a deep understanding of standards and certifications. Wafer style check valves should comply with industry standards such as ISO, API, or ASME, which guarantee that they meet safety and performance criteria. Working with manufacturers who adhere to these standards gives peace of mind that the valves are not only effective but also safe for industrial use. Trustworthiness is paramount, not only in the durability and performance of the valve but also in the manufacturer’s support and customer service. Opt for manufacturers with a proven track record and comprehensive after-sales support. Access to technical support and replacement parts is crucial for maintaining system integrity and minimizing downtime. A case study worth mentioning is a project I managed for a water treatment facility. The facility faced issues with valve failure and energy inefficiency. After assessing the operational requirements and current challenges, we recommended switching to wafer style check valves. Post-installation, the facility reported a 15% increase in efficiency and significantly reduced maintenance costs. This real-life example underscores the importance of choosing the right valve for specific applications and how such a choice can lead to operational excellence. Finally, the installation process and ongoing maintenance of wafer style check valves should not be overlooked. Proper alignment and secure sealing during installation are critical to preventing leakage and ensuring long-term performance. Regular inspections and maintenance routines should be established to detect early signs of wear or potential failure. In conclusion, wafer style check valves are an excellent choice for industries requiring compact, efficient, and durable solutions for flow control. By focusing on material compatibility, understanding different actuating mechanisms, adhering to industry standards, and ensuring reliable manufacturer support, industrial setups can achieve notable improvements in both cost savings and system reliability.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024