1 月 . 19, 2025 02:06 Back to list

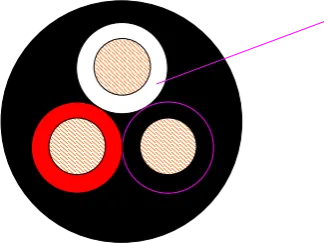

vulcanized seat flange butterfly valve

Vulcanized seat flange butterfly valves have emerged as essential components in various industries, renowned for their efficiency and durability. These valves are crucial in applications where precise fluid control is necessary, especially in sectors like water treatment, chemical processing, and oil and gas. Here’s a deep dive into the distinctive features, benefits, and considerations when selecting vulcanized seat flange butterfly valves.

Quality assurance is an essential aspect when selecting a vulcanized seat flange butterfly valve. Industry leaders and experts recommend sourcing these valves from established manufacturers known for their rigorous quality control processes. Reputable manufacturers often subject their products to extensive testing—this includes pressure, temperature, and cycle tests—to verify the valve's performance across various operational scenarios. Such stringent testing ensures that the valve can withstand harsh conditions and retain its operational integrity. Moreover, the choice of materials is crucial in the manufacturing process of vulcanized seat flange butterfly valves. Commonly used materials include stainless steel, ductile iron, and high-performance alloys, each offering specific advantages depending on the application. For corrosive environments, corrosion-resistant alloys are preferable, while high-temperature applications would benefit from materials with a higher thermal tolerance. Consulting with industry professionals can provide valuable insights into which material is best suited for specific operating conditions. Trust in vulcanized seat flange butterfly valves is fortified by the comprehensive warranties provided by manufacturers. These warranties are a testament to the manufacturer's confidence in their product's reliability and longevity. Customers can rely on these assurances, knowing that their investment is protected. Establishing a relationship with credible suppliers known for their after-sales support is equally important, as this can provide invaluable assistance in the event of unforeseen issues. In summary, vulcanized seat flange butterfly valves are definitive components that enhance operational efficiency through their durability, precise control, and ease of installation. Selecting the right valve from a trustworthy manufacturer ensures that industries can maintain robust systems with minimal disruption. This expert advice underscores the importance of making informed decisions when investing in critical infrastructure components to ensure long-term operational success.

Quality assurance is an essential aspect when selecting a vulcanized seat flange butterfly valve. Industry leaders and experts recommend sourcing these valves from established manufacturers known for their rigorous quality control processes. Reputable manufacturers often subject their products to extensive testing—this includes pressure, temperature, and cycle tests—to verify the valve's performance across various operational scenarios. Such stringent testing ensures that the valve can withstand harsh conditions and retain its operational integrity. Moreover, the choice of materials is crucial in the manufacturing process of vulcanized seat flange butterfly valves. Commonly used materials include stainless steel, ductile iron, and high-performance alloys, each offering specific advantages depending on the application. For corrosive environments, corrosion-resistant alloys are preferable, while high-temperature applications would benefit from materials with a higher thermal tolerance. Consulting with industry professionals can provide valuable insights into which material is best suited for specific operating conditions. Trust in vulcanized seat flange butterfly valves is fortified by the comprehensive warranties provided by manufacturers. These warranties are a testament to the manufacturer's confidence in their product's reliability and longevity. Customers can rely on these assurances, knowing that their investment is protected. Establishing a relationship with credible suppliers known for their after-sales support is equally important, as this can provide invaluable assistance in the event of unforeseen issues. In summary, vulcanized seat flange butterfly valves are definitive components that enhance operational efficiency through their durability, precise control, and ease of installation. Selecting the right valve from a trustworthy manufacturer ensures that industries can maintain robust systems with minimal disruption. This expert advice underscores the importance of making informed decisions when investing in critical infrastructure components to ensure long-term operational success.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024