1 月 . 19, 2025 02:28 Back to list

ci flanged ball valve

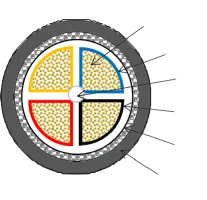

In the realm of industrial plumbing and fluid management, the CI flanged ball valve stands out as a critical component that ensures both reliability and performance. These valves have become indispensable in a variety of applications, ranging from oil and gas to water treatment facilities. Their importance is highlighted by their unique design and robust construction, which enable efficient control over fluid flow in high-pressure environments. Here, we delve into why the CI flanged ball valve is a cornerstone for experts seeking dependable solutions.

Incorporating CI flanged ball valves into existing systems requires expertise to maximize operational efficiency. Professionals recommend conducting a thorough analysis of the pipeline characteristics and operating conditions to select the appropriate valve size and pressure rating. Furthermore, employing skilled technicians for installation ensures optimal alignment and tight sealing of the flanges, thus preventing potential leaks or premature wear. Maintaining System Integrity Regular maintenance is paramount to preserving the integrity of CI flanged ball valves. Periodic inspections and performance evaluations ensure that the valves operate within their specified parameters. This involves checking for signs of wear, corrosion, or any material degradation that could compromise their function. By adhering to a rigorous maintenance schedule, industries can extend the lifecycle of these valves, maintaining system integrity and safety. Purchasing Considerations and Expertise Selecting the right CI flanged ball valve involves more than choosing the correct dimensions. It's crucial to engage with reputable manufacturers who provide comprehensive product information and support. High-quality CI ball valves are characterized by certified manufacturing processes, ensuring that they meet or exceed industry standards for safety and performance. By collaborating with trusted suppliers, stakeholders can make informed decisions with confidence in the reliability and quality of their chosen components. Future Trends and Innovations The future of CI flanged ball valves lies in ongoing advancements in material technology and automation. Emerging materials that offer superior resistance to extreme conditions are being explored to enhance valve longevity. Moreover, integrating smart technology is transforming how these valves operate, allowing for remote monitoring and automated control, thereby increasing efficiency and safety. In conclusion, the CI flanged ball valve is not merely a component; it is a linchpin of industrial fluid control systems. Its enduring popularity is a testament to its superior design, reliability, and unmatched durability. Industries seeking to maintain high standards of operation and safety continue to rely on the proven performance of CI flanged ball valves, a testament to their authority in the world of fluid management.

Incorporating CI flanged ball valves into existing systems requires expertise to maximize operational efficiency. Professionals recommend conducting a thorough analysis of the pipeline characteristics and operating conditions to select the appropriate valve size and pressure rating. Furthermore, employing skilled technicians for installation ensures optimal alignment and tight sealing of the flanges, thus preventing potential leaks or premature wear. Maintaining System Integrity Regular maintenance is paramount to preserving the integrity of CI flanged ball valves. Periodic inspections and performance evaluations ensure that the valves operate within their specified parameters. This involves checking for signs of wear, corrosion, or any material degradation that could compromise their function. By adhering to a rigorous maintenance schedule, industries can extend the lifecycle of these valves, maintaining system integrity and safety. Purchasing Considerations and Expertise Selecting the right CI flanged ball valve involves more than choosing the correct dimensions. It's crucial to engage with reputable manufacturers who provide comprehensive product information and support. High-quality CI ball valves are characterized by certified manufacturing processes, ensuring that they meet or exceed industry standards for safety and performance. By collaborating with trusted suppliers, stakeholders can make informed decisions with confidence in the reliability and quality of their chosen components. Future Trends and Innovations The future of CI flanged ball valves lies in ongoing advancements in material technology and automation. Emerging materials that offer superior resistance to extreme conditions are being explored to enhance valve longevity. Moreover, integrating smart technology is transforming how these valves operate, allowing for remote monitoring and automated control, thereby increasing efficiency and safety. In conclusion, the CI flanged ball valve is not merely a component; it is a linchpin of industrial fluid control systems. Its enduring popularity is a testament to its superior design, reliability, and unmatched durability. Industries seeking to maintain high standards of operation and safety continue to rely on the proven performance of CI flanged ball valves, a testament to their authority in the world of fluid management.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024