1 月 . 17, 2025 01:56 Back to list

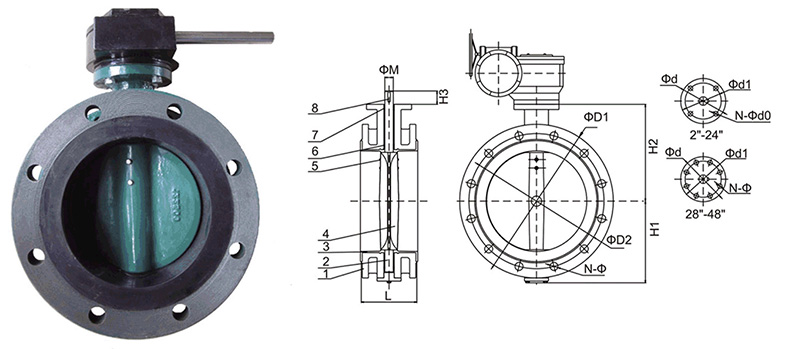

u type butterfly valve

Butterfly valves have long served as crucial components in various industrial and commercial applications due to their efficient flow regulation, compact design, and cost-effectiveness. The unique subtype, the U type butterfly valve, has become increasingly prominent in recent years. This article delves into the nuances of U type butterfly valves, providing insights drawn from extensive experience and expertise, underscored by authoritative technical knowledge and a focus on trustworthiness.

The construction of U type butterfly valves also promotes a high degree of reliability. The unibody design inherently eliminates potential leak paths present in multi-piece flanged connections, enhancing the valve's integrity. This reliability is further reinforced by rigorous testing and quality assurance practices adhered to by leading manufacturers. Adhering to international standards, these valves are tested for performance metrics such as cycle life, thermal resilience, and pressure holding capacity, thereby ensuring that they meet or exceed industry expectations. Moreover, the authoritative aspect of U type butterfly valves is evidenced by their widespread endorsement across industry standards and specifications. Compliance with recognized standards such as API, ANSI, and ISO serves as a testament to their performance capabilities. When selecting a U type valve, users can rely on these certifications to gauge the quality and durability of the product, enhancing trust in its operational effectiveness. Trustworthiness in U type butterfly valves is not solely a function of their physical attributes but is also built on the reputation of the manufacturers. Companies that prioritize innovation, sustainability, and customer satisfaction tend to produce valves that consistently meet user requirements. Recommendations from industry peers and positive testimonials further bolster the valve's reputation, providing prospective users with the confidence needed to make informed decisions. In conclusion, the U type butterfly valve is a highly efficient and reliable solution tailored to meet the demands of various industrial applications. By combining a sophisticated design with material versatility and adherence to high-quality standards, these valves deliver exceptional performance across multiple parameters. Their adoption not only enhances operational efficiency but also reinforces sustainability efforts through reduced energy use and extended service life. For businesses looking to optimize their fluid control systems, the U type butterfly valve represents a merging of expertise and practical reliability, making it a worthy investment in pursuit of operational excellence.

The construction of U type butterfly valves also promotes a high degree of reliability. The unibody design inherently eliminates potential leak paths present in multi-piece flanged connections, enhancing the valve's integrity. This reliability is further reinforced by rigorous testing and quality assurance practices adhered to by leading manufacturers. Adhering to international standards, these valves are tested for performance metrics such as cycle life, thermal resilience, and pressure holding capacity, thereby ensuring that they meet or exceed industry expectations. Moreover, the authoritative aspect of U type butterfly valves is evidenced by their widespread endorsement across industry standards and specifications. Compliance with recognized standards such as API, ANSI, and ISO serves as a testament to their performance capabilities. When selecting a U type valve, users can rely on these certifications to gauge the quality and durability of the product, enhancing trust in its operational effectiveness. Trustworthiness in U type butterfly valves is not solely a function of their physical attributes but is also built on the reputation of the manufacturers. Companies that prioritize innovation, sustainability, and customer satisfaction tend to produce valves that consistently meet user requirements. Recommendations from industry peers and positive testimonials further bolster the valve's reputation, providing prospective users with the confidence needed to make informed decisions. In conclusion, the U type butterfly valve is a highly efficient and reliable solution tailored to meet the demands of various industrial applications. By combining a sophisticated design with material versatility and adherence to high-quality standards, these valves deliver exceptional performance across multiple parameters. Their adoption not only enhances operational efficiency but also reinforces sustainability efforts through reduced energy use and extended service life. For businesses looking to optimize their fluid control systems, the U type butterfly valve represents a merging of expertise and practical reliability, making it a worthy investment in pursuit of operational excellence.

Share

Prev:

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024