11 月 . 04, 2024 16:07 Back to list

stainless steel globe valve

Understanding Stainless Steel Globe Valves Features and Applications

Stainless steel globe valves are essential components in various industrial applications, renowned for their reliable performance and durability. These valves are designed to control the flow of liquids and gases within a piping system, making them critical in sectors such as oil and gas, water treatment, chemical manufacturing, and power generation.

Construction and Design

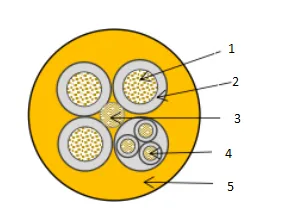

The globe valve features a spherical body that houses a movable disk over an opening, which regulates flow. Unlike other types of valves, the design of the globe valve allows for throttling, providing precise control over fluid movement. Stainless steel, commonly utilized in the construction of these valves, offers significant advantages due to its corrosion resistance, strength, and longevity. This material is particularly advantageous in applications that involve aggressive fluids or extreme temperatures.

Advantages of Stainless Steel

The use of stainless steel in manufacturing globe valves enhances several key attributes

1. Corrosion Resistance Stainless steel contains chromium, which forms a passive layer of oxide on the surface, protecting it from rust and corrosion. This property makes stainless steel globe valves an excellent choice for harsh environments, where exposure to moisture or chemicals could pose a risk to valve integrity.

2. Durability Stainless steel is known for its strength and toughness. Valve components made from this material can withstand high pressure and temperature changes without deforming or failing, ensuring longer operational life.

3. Hygienic Properties In industries such as food processing and pharmaceuticals, the hygienic properties of stainless steel are crucial. Its non-porous surface does not harbor bacteria or other contaminants, making it an ideal choice for applications requiring strict cleanliness standards.

stainless steel globe valve

Applications

Stainless steel globe valves find use across various industries due to their versatility and reliability. Some typical applications include

- Oil and Gas Industry These valves are used in upstream, midstream, and downstream processes to control the flow of crude oil, natural gas, and refined products. Their ability to handle high-pressure applications makes them indispensable in this sector.

- Chemical Manufacturing In chemical processes, maintaining control over the flow of reactants is critical. Stainless steel globe valves provide the required precision, ensuring safe and efficient processing.

- Water Treatment Globe valves are commonly employed in water treatment facilities to manage the flow of water through filtration and purification systems. Their durability ensures long-term functionality in these critical applications.

- Power Generation The power sector utilizes stainless steel globe valves in various applications, including steam and cooling systems, where they help manage flow rates and pressures effectively.

Conclusion

In summary, stainless steel globe valves are vital components that provide effective flow control across numerous industries. Their corrosion resistance, durability, and hygienic properties make them suitable for a wide range of applications, ensuring reliable performance and longevity. As industries continue to evolve and demands increase, the importance of robust and efficient valve solutions, such as stainless steel globe valves, will remain paramount. Understanding their features and benefits allows engineers and operators to make informed decisions regarding material selection and valve application, ultimately contributing to the efficiency and safety of industrial processes.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024