11 月 . 04, 2024 16:04 Back to list

Double Ball Rubber Joint Manufacturing Facility for Efficient Connections and Performance

The Essential Role of Double Ball Rubber Joints in Modern Engineering

In the contemporary landscape of engineering and manufacturing, the demand for versatile and durable components has never been greater. Among these essential components, the double ball rubber joint stands out as a critical element in various applications, providing flexibility, shock absorption, and structural integrity. This article explores the significance of double ball rubber joints, the manufacturing process involved, and their wide-ranging applications.

Understanding Double Ball Rubber Joints

Double ball rubber joints are flexible connectors designed to absorb vibrations and accommodate misalignment between connected piping systems. Typically made from high-quality rubber and reinforced with steel, these joints consist of two metallic balls that are encased in a rubber body, allowing for multidirectional movement. This unique structure enables them to absorb shocks, reducing stress on the piping systems, which is particularly important in dynamic environments such as industrial machinery, automotive, and HVAC systems.

The Manufacturing Process

The production of double ball rubber joints involves several precise steps to ensure quality and performance

. The process begins with the selection of raw materials, primarily high-grade rubber compounds and robust metallic components. Manufacturers prioritize materials that can withstand high pressure and temperature fluctuations, ensuring durability and reliability.Once the materials are chosen, the next step is molding. The rubber is heated and shaped around the metallic balls to create the desired form. This is usually done using advanced rubber injection molding techniques that facilitate precision and consistency in product output. After molding, the joints undergo rigorous quality testing to verify their strength, flexibility, and resistance to environmental factors such as heat, corrosion, and abrasion.

double ball rubber joint factory

Finally, the products are subjected to stringent inspection protocols before packaging and distribution. This careful attention to detail in the manufacturing process guarantees that the finished double ball rubber joints meet or exceed industry standards, ensuring that they perform optimally in various applications.

Applications of Double Ball Rubber Joints

The versatility of double ball rubber joints makes them ideal for numerous applications across various industries. One prominent usage is in the construction and maintenance of piping systems. These joints are extensively utilized in water treatment plants, chemical processing facilities, and power generation, where they manage the flow of liquids and gases while absorbing vibrations and minimizing wear.

In the automotive industry, double ball rubber joints play a crucial role in the suspension systems of vehicles. They provide the necessary flexibility to accommodate changes in terrain, ensuring a smooth ride while protecting vital components from excessive stress. Additionally, these joints are crucial in minimizing noise and enhancing passenger comfort.

Moreover, double ball rubber joints are utilized in HVAC systems. They allow for the necessary movements caused by thermal expansion and contraction while maintaining a tight seal to prevent leaks. This durability and flexibility contribute to the overall efficiency of heating and cooling systems, making them a favorite among engineers and contractors alike.

Conclusion

Double ball rubber joints are indispensable components in modern engineering, providing the necessary flexibility and durability to meet the demands of various applications. Their advanced manufacturing processes ensure high quality and reliability, making them a critical choice in industries ranging from construction to automotive and HVAC. As technology evolves and industries grow, the importance of such innovative components will only continue to rise, solidifying their role in enhancing performance and efficiency in systems worldwide. With ongoing advancements in materials and manufacturing techniques, the future of double ball rubber joints looks promising, paving the way for even more remarkable applications in the years to come.

Share

-

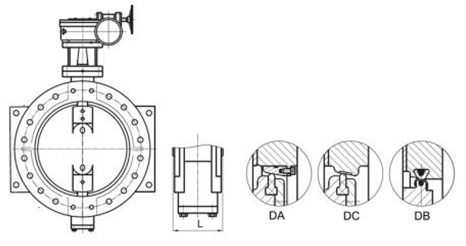

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024