2 月 . 10, 2025 10:29 Back to list

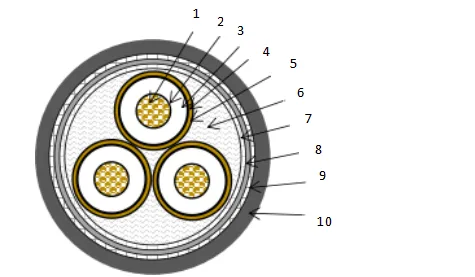

Type W Three-Conductor Portable Power Cable 2kV

Rubber expansion joints are indispensable components in various industrial systems, serving critical functions such as absorbing movement, reducing mechanical noise, and compensating for misalignment. As a veteran in the industry, it gives me a resolute understanding of how the pricing of these components can vary based on several intrinsic and extrinsic factors. Understanding these aspects can help organizations make informed decisions that align with their operational and financial objectives.

Market dynamics also play a significant role in the pricing structure of rubber expansion joints. Raw material availability, geopolitical factors affecting trade, and global demand and supply fluctuations can all impact costs. As such, it's advisable for procurement teams to stay informed about these external factors, which could suggest timing purchases strategically to outmaneuver sudden price shifts. In recent years, technological advances have also paved the way for smart expansion joints equipped with sensors that monitor performance and predict maintenance needs. While these are more costly upfront, their ability to optimize system efficiency and prevent unplanned outages can deliver substantial economic benefits over time. When budgeting for rubber expansion joints, it’s also wise to consider the total cost of ownership. This includes not only the purchase price but also installation costs, maintenance requirements, and potential downtime associated with failure, which can significantly outweigh the initial outlay. Concluding with a practical viewpoint, businesses should approach the acquisition of rubber expansion joints as a strategic investment, evaluating all factors meticulously to derive maximum value. Partnering with expert suppliers who demonstrate a commitment to quality and customer satisfaction can facilitate this process, ensuring that the chosen joints match the unique demands of the intended application, ultimately supporting operational excellence and financial efficiency. Keeping these perspectives in mind will enable organizations to not only secure cost-effective solutions but also align these critical components with their broader operational strategies, fostering long-term sustainability and competitive advantage.

Market dynamics also play a significant role in the pricing structure of rubber expansion joints. Raw material availability, geopolitical factors affecting trade, and global demand and supply fluctuations can all impact costs. As such, it's advisable for procurement teams to stay informed about these external factors, which could suggest timing purchases strategically to outmaneuver sudden price shifts. In recent years, technological advances have also paved the way for smart expansion joints equipped with sensors that monitor performance and predict maintenance needs. While these are more costly upfront, their ability to optimize system efficiency and prevent unplanned outages can deliver substantial economic benefits over time. When budgeting for rubber expansion joints, it’s also wise to consider the total cost of ownership. This includes not only the purchase price but also installation costs, maintenance requirements, and potential downtime associated with failure, which can significantly outweigh the initial outlay. Concluding with a practical viewpoint, businesses should approach the acquisition of rubber expansion joints as a strategic investment, evaluating all factors meticulously to derive maximum value. Partnering with expert suppliers who demonstrate a commitment to quality and customer satisfaction can facilitate this process, ensuring that the chosen joints match the unique demands of the intended application, ultimately supporting operational excellence and financial efficiency. Keeping these perspectives in mind will enable organizations to not only secure cost-effective solutions but also align these critical components with their broader operational strategies, fostering long-term sustainability and competitive advantage.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024