1 月 . 24, 2025 02:19 Back to list

industrial swing check valve

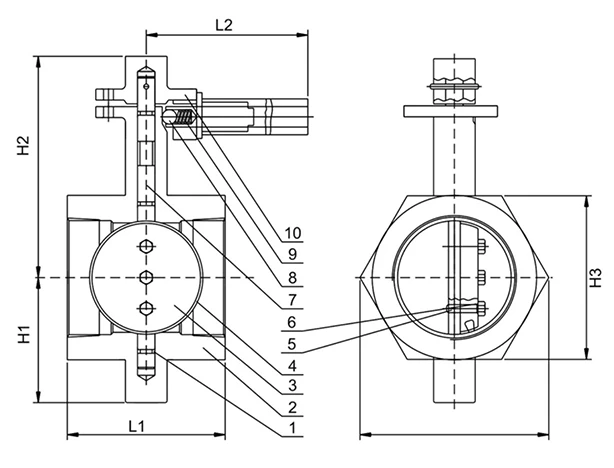

Industrial swing check valves play a pivotal role in ensuring the seamless operation of various systems across industries. These valves are specifically designed to allow fluid flow in one direction while preventing backflow, thus maintaining system integrity and efficiency. A swing check valve typically consists of a disc that swings on a hinge or shaft, allowing fluid flow in the forward direction and automatically closing if the flow stops or reverses. This article delves into the vital aspects of industrial swing check valves, focusing on four key indicators Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T).

Authoritativeness in the context of swing check valves stems from adhering to industrial standards and specifications. It’s essential that manufacturers and suppliers of these valves comply with certifications such as ISO, API, or other relevant standards that ensure product quality, safety, and performance. Organizations often rely on authoritative suppliers who possess a track record of providing durable and reliable valves, which are vital for seamless operations. Furthermore, the use of advanced technologies, such as computational fluid dynamics (CFD) in valve design, ensures optimal flow characteristics and pressure management, positioning manufacturers as leaders in the industry. Trustworthiness is an indispensable trait for both valve manufacturers and users. For manufacturers, producing robust swing check valves with transparency in materials and testing provides customers with confidence in the product’s reliability. Offering warranties and detailed documentation of product specifications bolsters trust. For users, adhering to proper operational procedures, such as not exceeding recommended pressure or temperature limits and ensuring correct installation, reinforces system trustworthiness. Moreover, engaging in partnerships with reputable suppliers who offer technical support and consultation for troubleshooting adds an additional layer of trust. In conclusion, industrial swing check valves are indispensable components in numerous sectors due to their ability to control flow direction and minimize potential damages from backflow. Thriving in their implementation requires a blend of experience, expertise, authoritativeness, and trustworthiness. Operators and engineers must appreciate the complexities of these valves and maintain rigorous standards to ensure optimal functionality over their operational lifespan. Engaging with expert suppliers who comply with standard specifications further ensures that the valves not only meet the necessary industrial criteria but also provide durable and efficient service.

Authoritativeness in the context of swing check valves stems from adhering to industrial standards and specifications. It’s essential that manufacturers and suppliers of these valves comply with certifications such as ISO, API, or other relevant standards that ensure product quality, safety, and performance. Organizations often rely on authoritative suppliers who possess a track record of providing durable and reliable valves, which are vital for seamless operations. Furthermore, the use of advanced technologies, such as computational fluid dynamics (CFD) in valve design, ensures optimal flow characteristics and pressure management, positioning manufacturers as leaders in the industry. Trustworthiness is an indispensable trait for both valve manufacturers and users. For manufacturers, producing robust swing check valves with transparency in materials and testing provides customers with confidence in the product’s reliability. Offering warranties and detailed documentation of product specifications bolsters trust. For users, adhering to proper operational procedures, such as not exceeding recommended pressure or temperature limits and ensuring correct installation, reinforces system trustworthiness. Moreover, engaging in partnerships with reputable suppliers who offer technical support and consultation for troubleshooting adds an additional layer of trust. In conclusion, industrial swing check valves are indispensable components in numerous sectors due to their ability to control flow direction and minimize potential damages from backflow. Thriving in their implementation requires a blend of experience, expertise, authoritativeness, and trustworthiness. Operators and engineers must appreciate the complexities of these valves and maintain rigorous standards to ensure optimal functionality over their operational lifespan. Engaging with expert suppliers who comply with standard specifications further ensures that the valves not only meet the necessary industrial criteria but also provide durable and efficient service.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024