2 月 . 01, 2025 02:06 Back to list

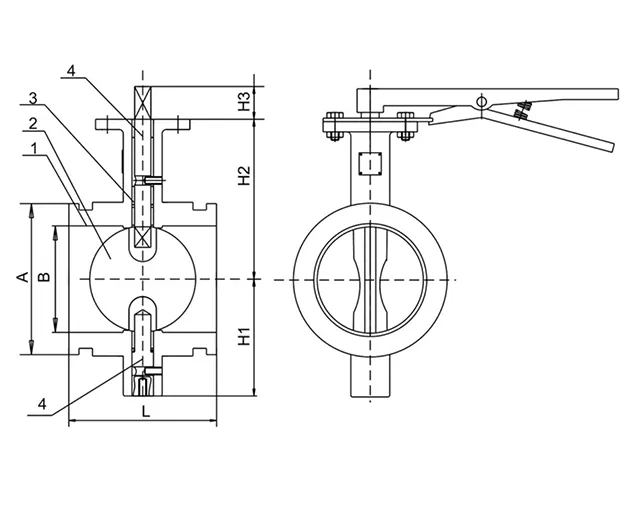

high performance butterfly valve

High performance butterfly valves have transformed various industries by offering reliable and efficient flow control solutions. These valves are specially designed to handle high-pressure and high-temperature conditions, making them an essential component in sectors like oil and gas, petrochemicals, power generation, and water treatment.

Trustworthiness is cemented through rigorous testing processes. Each valve undergoes comprehensive quality control checks to certify its performance under specified conditions. This ensures that when a high performance butterfly valve is in place, users can trust it will perform as expected, minimizing the risk of operational failures. In operational terms, these valves contribute significantly to the efficiency of processes. By providing precise flow control, they reduce energy consumption, which is not only cost-effective but also environmentally friendly. Advanced models of high performance butterfly valves are designed for automation, integrating seamlessly with computer systems for remote monitoring and control, enhancing operational efficiency further. The market for high performance butterfly valves continues to grow as industries seek more reliable and efficient solutions. Manufacturers are also constantly innovating, using cutting-edge technology to enhance valve performance. This includes improvements in sealing technologies and actuation methods that offer even greater precision and control. In conclusion, high performance butterfly valves stand out as indispensable components in modern industrial applications. Their design, efficiency, durability, and the trust they garner due to rigorous manufacturing and testing make them a primary choice for industries that cannot compromise on performance and reliability. As technology advances, these valves are set to become even more integral to diverse industrial operations, ensuring they remain at the forefront of flow control solutions.

Trustworthiness is cemented through rigorous testing processes. Each valve undergoes comprehensive quality control checks to certify its performance under specified conditions. This ensures that when a high performance butterfly valve is in place, users can trust it will perform as expected, minimizing the risk of operational failures. In operational terms, these valves contribute significantly to the efficiency of processes. By providing precise flow control, they reduce energy consumption, which is not only cost-effective but also environmentally friendly. Advanced models of high performance butterfly valves are designed for automation, integrating seamlessly with computer systems for remote monitoring and control, enhancing operational efficiency further. The market for high performance butterfly valves continues to grow as industries seek more reliable and efficient solutions. Manufacturers are also constantly innovating, using cutting-edge technology to enhance valve performance. This includes improvements in sealing technologies and actuation methods that offer even greater precision and control. In conclusion, high performance butterfly valves stand out as indispensable components in modern industrial applications. Their design, efficiency, durability, and the trust they garner due to rigorous manufacturing and testing make them a primary choice for industries that cannot compromise on performance and reliability. As technology advances, these valves are set to become even more integral to diverse industrial operations, ensuring they remain at the forefront of flow control solutions.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024