10 月 . 05, 2024 19:31 Back to list

Flexible Rubber Expansion Joint for Galvanized Piping Systems and Applications

Understanding Galvanized Rubber Expansion Joints

Galvanized rubber expansion joints are critical components in various industrial applications, designed to accommodate movement and absorb shock in piping systems. These joints serve an essential role in preventing damage caused by thermal expansion, vibrations, and pressure fluctuations within pipes.

Expansion joints are typically made from a combination of rubber and metal. The rubber provides flexibility, allowing for movement while the galvanized metal structure offers durability and resistance to environmental factors. The galvanization process, which involves coating steel with a layer of zinc, enhances the joint's resistance to corrosion and extends its lifespan, making it especially useful in harsh operating conditions.

One of the primary benefits of using galvanized rubber expansion joints is their ability to absorb movements generated by thermal expansion. As temperatures fluctuate, materials expand and contract. Without proper accommodation for these movements, pipes can experience stress, leading to cracks or ruptures. Expansion joints absorb this stress, effectively protecting the integrity of the piping system.

In addition to thermal movement, these joints also mitigate vibrations and noise within piping systems. Vibration can be caused by various factors, including pumps, compressors, and other machinery. Over time, relentless vibrations can lead to premature wear and failure of piping components. Galvanized rubber expansion joints act as shock absorbers, preventing vibrations from transmitting through the system and ensuring quieter operation.

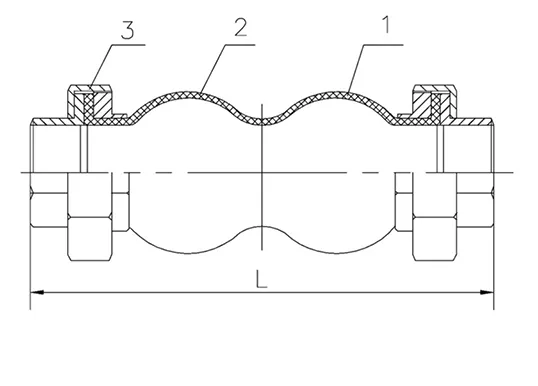

galvanized rubber expansion joint

Moreover, galvanized rubber expansion joints are versatile and suitable for a wide range of applications, including HVAC systems, chemical processing plants, and water treatment facilities

. Their adaptability allows them to fit into various machinery and equipment designs, providing effective solutions in environments that demand high reliability and durability.When selecting a galvanized rubber expansion joint, several factors must be considered, including the type of media being transported (liquid or gas), temperature and pressure ratings, and the specific movements expected in the system. Proper sizing and selection ensure optimal performance, safety, and longevity of the expansion joint and the piping system as a whole.

Maintenance of galvanized rubber expansion joints is relatively straightforward. Regular inspections can help identify wear and tear, ensuring issues are addressed before they lead to severe problems. Signs of deterioration may include cracking, leaking, or visible corrosion. Addressing these signs promptly can prevent costly repairs and downtime.

In conclusion, galvanized rubber expansion joints are indispensable components in industrial piping systems, enhancing reliability and performance. Their ability to accommodate movement, absorb shock, and reduce vibrations makes them an essential choice for various applications. Proper installation and maintenance will ensure these joints continue to protect piping systems from the stresses of operation, promoting efficiency and longevity in industrial processes.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024