10 月 . 05, 2024 19:00 Back to list

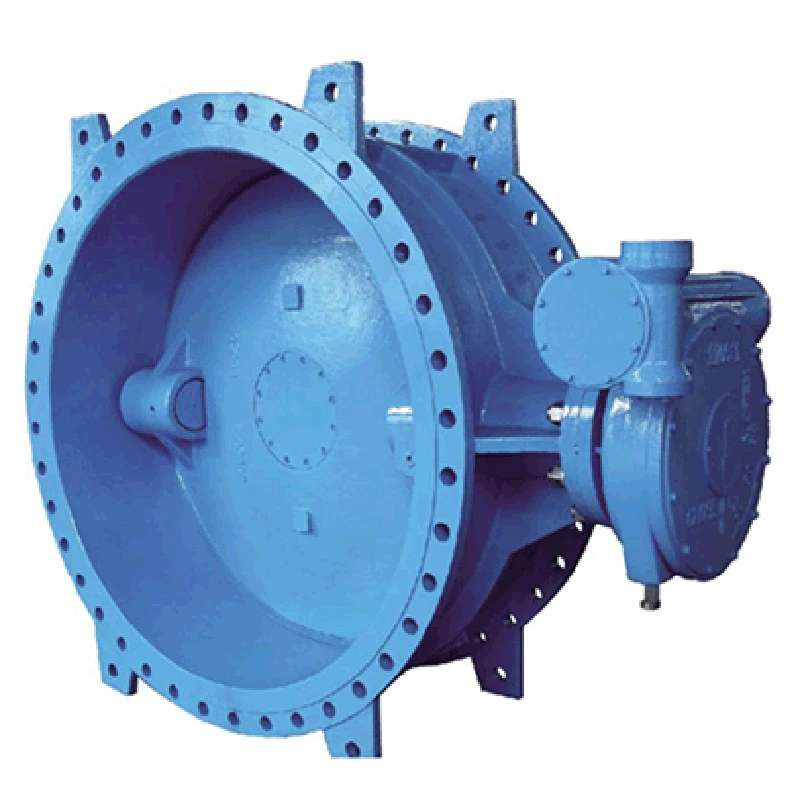

ductile iron ball valve

The Versatility of Ductile Iron Ball Valves

Ductile iron ball valves have gained immense popularity in various industrial applications due to their remarkable strength, durability, and resistance to wear and corrosion. Crafted from a high-strength iron alloy, these valves not only ensure reliable performance but also provide a cost-effective solution for fluid control. In this article, we will explore the features, benefits, applications, and maintenance of ductile iron ball valves, highlighting why they are an essential component in modern piping systems.

Understanding Ductile Iron

Ductile iron, also known as spheroidal graphite iron or nodular cast iron, is an enhanced form of cast iron. It is characterized by its unique microstructure, wherein graphite takes the shape of small spheres. This structure imparts significant strength, ductility, and toughness compared to traditional cast iron. As a result, ductile iron can withstand higher pressures and stress levels, making it an ideal material for valves used in demanding environments.

Key Features of Ductile Iron Ball Valves

1. Robust Construction Ductile iron ball valves are designed to handle high-pressure applications, ensuring leak-free performance. Their solid body offers superior durability against wear and tear, making them suitable for various fluid types, including corrosive substances.

2. Versatile Design These valves come in a variety of sizes and configurations, accommodating different pipe diameters and flow requirements. This versatility makes them suitable for multiple industrial sectors, from water supply systems to oil and gas applications.

3. Excellent Sealing Capability Ductile iron ball valves utilize a spherical disc that rotates to open or close the flow, providing a tight seal when closed. This design minimizes the risk of leakage and allows for precise flow control, contributing to efficient system operation.

4. Ease of Operation The quarter-turn operation of ball valves simplifies the process of opening and closing the valve, making it user-friendly. This feature is particularly advantageous in situations where rapid flow adjustment is required.

5. Resistance to Corrosion Many ductile iron ball valves come with protective coatings or linings that enhance their resistance to corrosion, thereby extending their lifespan. This characteristic is particularly important when dealing with aggressive fluids.

Benefits of Ductile Iron Ball Valves

ductile iron ball valve

2. Improved Safety With their robust design and reliable sealing capabilities, these valves contribute to operational safety by preventing leaks and minimizing the risk of accidents in industrial environments.

3. Environmental Considerations The longevity and efficiency of ductile iron ball valves help reduce waste and energy consumption, aligning with modern sustainability goals in many industries.

Applications of Ductile Iron Ball Valves

Ductile iron ball valves are utilized across a wide range of industries, including

- Water Treatment Essential for managing the flow of water in treatment facilities, ensuring effective filtration and distribution. - Oil and Gas Employed in pipelines to control the flow of crude oil, natural gas, and other petroleum products. - Chemical Processing Used to manage and control the flow of various chemicals in safe and efficient ways. - Food and Beverage Industry Ensuring sanitary conditions and precise flow control in processing lines.

Maintenance of Ductile Iron Ball Valves

To ensure the longevity and performance of ductile iron ball valves, regular maintenance is crucial. Operators should conduct periodic inspections to identify any signs of wear or damage. Lubricating the valve stem and inspecting seals for degradation can prevent operational failures. Additionally, maintaining proper pressure levels and ensuring the system is not subject to extreme temperatures will help sustain the valve's performance over time.

Conclusion

Ductile iron ball valves represent an essential innovation in industrial fluid control systems. Their combination of strength, versatility, and cost-effectiveness makes them a favored choice among engineers and operators. As industries continue to prioritize efficiency and safety, the role of ductile iron ball valves in ensuring smooth operations is more critical than ever. Whether in water treatment, oil and gas, or chemical processing, these valves are poised to remain a vital component of modern infrastructure for years to come.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024