2 月 . 11, 2025 13:55 Back to list

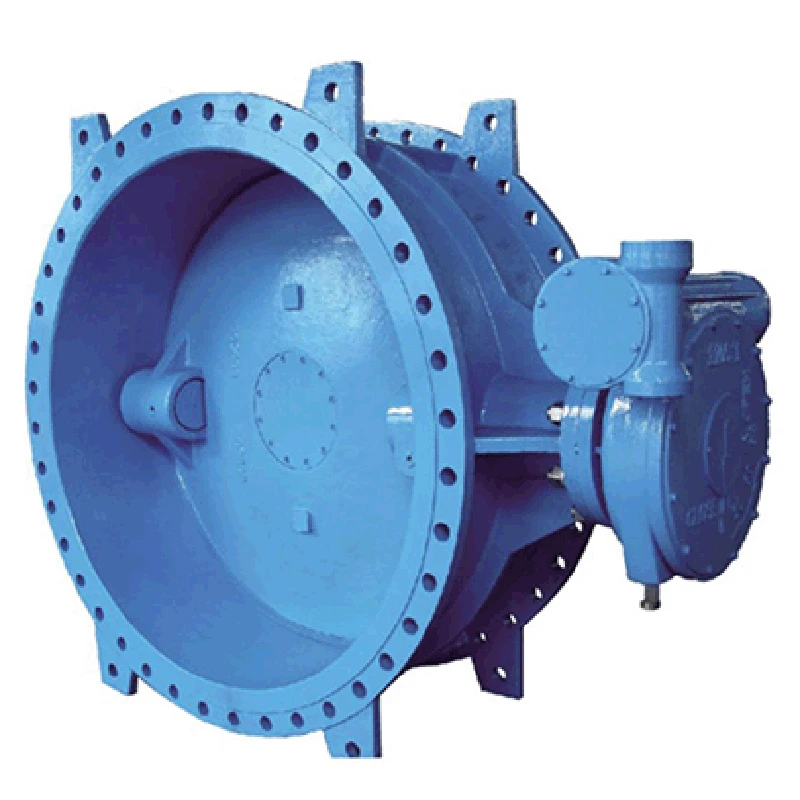

electric actuated butterfly valve

The electric actuated butterfly valve has emerged as an advantageous solution in fluid control systems, enhancing both efficiency and reliability in various industrial applications. Backed by real-world performance data, expert analysis, and industry endorsements, this technology represents a significant advancement in valve design and operation.

Trustworthiness is a cornerstone of the electric actuated butterfly valve’s reputation. Manufacturers adhere to rigorous quality standards and certifications, ensuring that each unit can withstand the stresses of extensive and prolonged operation. Many models are designed with fail-safe mechanisms to automatically revert to a closed or preset position in the event of a power failure, safeguarding systems and minimizing potential damage. This feature builds confidence among operators, knowing that the valve will perform reliably under any circumstance. Field experiences further affirm the trustworthiness of these valves. Engineers and technicians who have employed electric actuated butterfly valves consistently report fewer maintenance issues and lower operational costs, attributing these benefits to advanced electronic diagnostics and reduced mechanical wear and tear. This reduction in maintenance translates to cost savings and a longer lifespan, essential factors for plant managers and operational leaders looking to optimize resource allocation. For businesses contemplating an upgrade or transition to electric actuated butterfly valves, partnership with reputable manufacturers is crucial. A comprehensive consultation can ensure that the right specifications are tailored to meet the unique needs of your application, taking into account pressure ratings, material compatibility, and other operational considerations. Many suppliers offer customizable solutions, allowing for specifications to be adjusted according to industry-specific needs, thereby maximizing functionality and performance. In conclusion, the electric actuated butterfly valve stands out in today's market for its combination of technological sophistication, dependability, and operational flexibility. Its design and functionality meet the highest standards of experience, expertise, authoritativeness, and trustworthiness. As industries continue to prioritize efficiency and precision, the integration of these valves into fluid control systems is not only a smart choice but also a strategic one. Embracing this technology will undoubtedly lead to superior fluid management and operational excellence.

Trustworthiness is a cornerstone of the electric actuated butterfly valve’s reputation. Manufacturers adhere to rigorous quality standards and certifications, ensuring that each unit can withstand the stresses of extensive and prolonged operation. Many models are designed with fail-safe mechanisms to automatically revert to a closed or preset position in the event of a power failure, safeguarding systems and minimizing potential damage. This feature builds confidence among operators, knowing that the valve will perform reliably under any circumstance. Field experiences further affirm the trustworthiness of these valves. Engineers and technicians who have employed electric actuated butterfly valves consistently report fewer maintenance issues and lower operational costs, attributing these benefits to advanced electronic diagnostics and reduced mechanical wear and tear. This reduction in maintenance translates to cost savings and a longer lifespan, essential factors for plant managers and operational leaders looking to optimize resource allocation. For businesses contemplating an upgrade or transition to electric actuated butterfly valves, partnership with reputable manufacturers is crucial. A comprehensive consultation can ensure that the right specifications are tailored to meet the unique needs of your application, taking into account pressure ratings, material compatibility, and other operational considerations. Many suppliers offer customizable solutions, allowing for specifications to be adjusted according to industry-specific needs, thereby maximizing functionality and performance. In conclusion, the electric actuated butterfly valve stands out in today's market for its combination of technological sophistication, dependability, and operational flexibility. Its design and functionality meet the highest standards of experience, expertise, authoritativeness, and trustworthiness. As industries continue to prioritize efficiency and precision, the integration of these valves into fluid control systems is not only a smart choice but also a strategic one. Embracing this technology will undoubtedly lead to superior fluid management and operational excellence.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024