2 月 . 20, 2025 12:02 Back to list

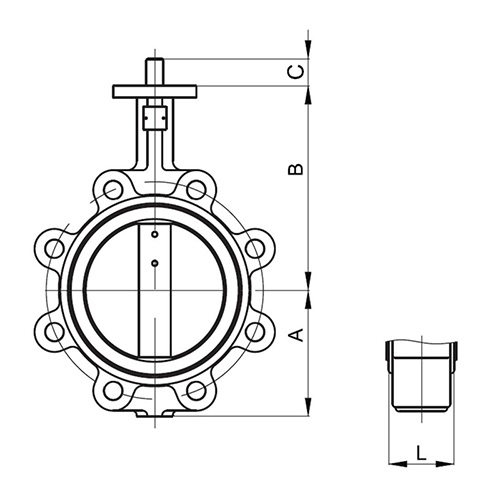

Grooved End Butterfly Valve

In the industrial world, where precision and durability are paramount, the choice of the right components can significantly impact the performance and efficiency of various systems. Among these components, the double sphere flange type rubber joint stands out as a crucial element designed to offer unparalleled flexibility, vibration reduction, and longevity.

From an authoritative standpoint, numerous industry standards govern the manufacturing and testing of double sphere flange type rubber joints. Adherence to these standards, such as ISO or ASTM, is non-negotiable, as they guarantee that the product holds up under industrial scrutiny. Reputable manufacturers subject their joints to rigorous testing before reaching the market, ensuring they meet or exceed these stringent requirements. This adherence to globally recognized standards not only ensures product quality but also builds trust with end-users. Trustworthiness in double sphere flange rubber joints can be measured by the long-term performance and reliability of the product. The best manufacturers offer warranties and after-sale support, reinforcing their confidence in the product's durability and functionality. Industry reviews and client testimonials become crucial here, providing potential buyers with real-world insights into performance. Such trusted feedback often points to the joint’s remarkable ability to reduce maintenance frequency and prevent costly system failures, making them an invaluable choice for engineers and plant operators. For those seeking to implement systems that require minimal intervention yet maintain high performance, these rubber joints are the go-to solution. In conclusion, the double sphere flange type rubber joint represents an intersection of innovation, expertise, and trust in industrial applications. With its ability to adapt to dynamic conditions while ensuring system integrity, it supports industries in achieving operational efficiency and reliability. The commitment to quality standards, continual innovation, and responsive customer support together establish it as the authoritative choice for modern engineering challenges.

From an authoritative standpoint, numerous industry standards govern the manufacturing and testing of double sphere flange type rubber joints. Adherence to these standards, such as ISO or ASTM, is non-negotiable, as they guarantee that the product holds up under industrial scrutiny. Reputable manufacturers subject their joints to rigorous testing before reaching the market, ensuring they meet or exceed these stringent requirements. This adherence to globally recognized standards not only ensures product quality but also builds trust with end-users. Trustworthiness in double sphere flange rubber joints can be measured by the long-term performance and reliability of the product. The best manufacturers offer warranties and after-sale support, reinforcing their confidence in the product's durability and functionality. Industry reviews and client testimonials become crucial here, providing potential buyers with real-world insights into performance. Such trusted feedback often points to the joint’s remarkable ability to reduce maintenance frequency and prevent costly system failures, making them an invaluable choice for engineers and plant operators. For those seeking to implement systems that require minimal intervention yet maintain high performance, these rubber joints are the go-to solution. In conclusion, the double sphere flange type rubber joint represents an intersection of innovation, expertise, and trust in industrial applications. With its ability to adapt to dynamic conditions while ensuring system integrity, it supports industries in achieving operational efficiency and reliability. The commitment to quality standards, continual innovation, and responsive customer support together establish it as the authoritative choice for modern engineering challenges.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024