1 月 . 19, 2025 00:53 Back to list

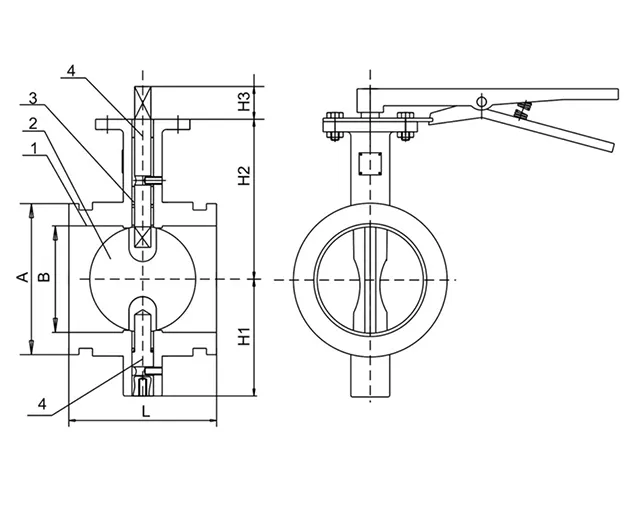

di wafer type butterfly valve

The world of industrial valves is broad, filled with an array of variations each serving distinct purposes. Among them, the DI wafer type butterfly valve stands out as an essential component in various sectors. Its unique design and functionality offer professionals in industries such as water treatment, chemical processing, and oil refineries a reliable solution for flow regulation.

In practical experience, operators have lauded DI wafer type butterfly valves for their versatility. They're capable of handling different types of media, from water to gases and even chemicals, thanks to their robust sealing mechanisms usually crafted from elastomers or PTFE. Moreover, their bidirectional capability minimizes the risk of accidental backflow, ensuring that operations remain orderly and safe. Installation and maintenance, another critical consideration for any industrial product, are relatively straightforward with the DI wafer type butterfly valve. Its design allows it to fit snugly between two flanges, and with fewer bolts required, both time and labor costs can be significantly diminished. Routine inspections are typically hassle-free, given the valve’s simplistic design which allows easy access to its components. The expertise involved in leveraging these valves lies not only in installation but also in choosing the correct specifications for a given application. Professionals must consider factors such as media type, pressure, and temperature to ensure optimal performance. Manufacturers usually offer a range of customization options, from materials to configurations, allowing the DI wafer type butterfly valve to be tailored precisely to meet operational demands. In conclusion, the DI wafer type butterfly valve embodies a blend of technological advancement, reliability, and cost-effectiveness. Its widespread use and the high regard from professionals underscore its significance in the industrial field. As industries evolve and demand more efficient systems, valves like these, with their proven track record, continue to play a pivotal role in facilitating precise control over fluid dynamics. For decision-makers looking for robust, durable solutions, understanding the comprehensive benefits and capabilities of the DI wafer type butterfly valve is essential.

In practical experience, operators have lauded DI wafer type butterfly valves for their versatility. They're capable of handling different types of media, from water to gases and even chemicals, thanks to their robust sealing mechanisms usually crafted from elastomers or PTFE. Moreover, their bidirectional capability minimizes the risk of accidental backflow, ensuring that operations remain orderly and safe. Installation and maintenance, another critical consideration for any industrial product, are relatively straightforward with the DI wafer type butterfly valve. Its design allows it to fit snugly between two flanges, and with fewer bolts required, both time and labor costs can be significantly diminished. Routine inspections are typically hassle-free, given the valve’s simplistic design which allows easy access to its components. The expertise involved in leveraging these valves lies not only in installation but also in choosing the correct specifications for a given application. Professionals must consider factors such as media type, pressure, and temperature to ensure optimal performance. Manufacturers usually offer a range of customization options, from materials to configurations, allowing the DI wafer type butterfly valve to be tailored precisely to meet operational demands. In conclusion, the DI wafer type butterfly valve embodies a blend of technological advancement, reliability, and cost-effectiveness. Its widespread use and the high regard from professionals underscore its significance in the industrial field. As industries evolve and demand more efficient systems, valves like these, with their proven track record, continue to play a pivotal role in facilitating precise control over fluid dynamics. For decision-makers looking for robust, durable solutions, understanding the comprehensive benefits and capabilities of the DI wafer type butterfly valve is essential.

Share

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024