2 月 . 12, 2025 11:08 Back to list

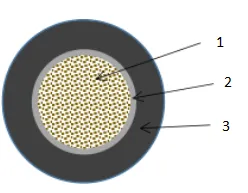

cast iron butterfly valve

Choosing the right valve is crucial for any industrial system, and the cast iron butterfly valve stands out as an exemplary choice. Known for its efficiency and reliability, this valve offers numerous advantages that cater to a wide array of industrial needs.

The authority of the cast iron butterfly valve is widely recognized due to its extensive application across various sectors, including petrochemicals, pharmaceuticals, and food and beverages. Many industry experts acknowledge its role in sustaining operational integrity and minimizing leakage risks, thereby confirming its status as a trusted component in systems requiring stringent regulatory compliance and safety standards. From an experience standpoint, feedback from field professionals who’ve utilized cast iron butterfly valves consistently points toward user satisfaction. Operators often cite the ease of use and the longevity of performance as significant benefits, noting the valve’s capability to withstand high-pressure environments without losing functionality. Safety and reliability remain paramount, and the cast iron butterfly valve excels with its trustworthy sealing mechanisms and robust construction. Whether deployed in high-risk chemical conveyance or municipal water supply systems, its reliability ensures peace of mind, significantly reducing the likelihood of environmental damage or material loss due to leakage. In conclusion, the cast iron butterfly valve emerges as an optimal choice for any industry prioritizing efficiency, cost-effectiveness, and reliability. Its straightforward design, combined with the robustness of cast iron, supports a long service life and stable performance across diverse applications. By investing in a cast iron butterfly valve, industries not only enhance their operational efficiency but also align with sustainable practices aiming for long-term success.

The authority of the cast iron butterfly valve is widely recognized due to its extensive application across various sectors, including petrochemicals, pharmaceuticals, and food and beverages. Many industry experts acknowledge its role in sustaining operational integrity and minimizing leakage risks, thereby confirming its status as a trusted component in systems requiring stringent regulatory compliance and safety standards. From an experience standpoint, feedback from field professionals who’ve utilized cast iron butterfly valves consistently points toward user satisfaction. Operators often cite the ease of use and the longevity of performance as significant benefits, noting the valve’s capability to withstand high-pressure environments without losing functionality. Safety and reliability remain paramount, and the cast iron butterfly valve excels with its trustworthy sealing mechanisms and robust construction. Whether deployed in high-risk chemical conveyance or municipal water supply systems, its reliability ensures peace of mind, significantly reducing the likelihood of environmental damage or material loss due to leakage. In conclusion, the cast iron butterfly valve emerges as an optimal choice for any industry prioritizing efficiency, cost-effectiveness, and reliability. Its straightforward design, combined with the robustness of cast iron, supports a long service life and stable performance across diverse applications. By investing in a cast iron butterfly valve, industries not only enhance their operational efficiency but also align with sustainable practices aiming for long-term success.

Share

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024