1 月 . 28, 2025 04:02 Back to list

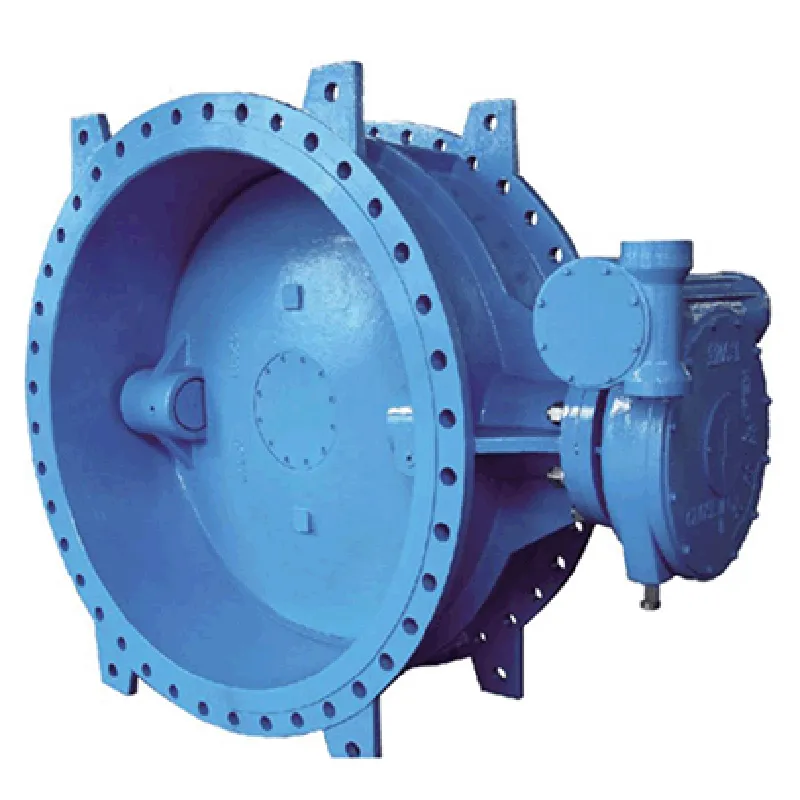

butterfly valve flange end

Butterfly valve flange ends have become an essential component in various industries, owing to their unique design and operational efficiency. These devices, renowned for their cost-effectiveness and versatility, are predominantly utilized in piping systems to regulate the flow of fluids. Understanding the nuances of butterfly valve flange ends not only enhances operational efficiency but also optimizes industrial processes across a plethora of sectors.

Trustworthiness of butterfly valve flange ends is amplified when considering manufacturers with a proven track record of delivering durable and reliable products. Reputable manufacturers invest in advanced manufacturing techniques and employ stringent quality control measures throughout the production process. This commitment to quality is reflected in the robustness and longevity of their valves, which perform consistently under harsh industrial conditions. Furthermore, ongoing field research and user feedback play significant roles in refining these products to better meet the evolving needs of industrial applications. The growing adoption of butterfly valve flange ends is also driven by their seamless integration with automated control systems. These valves can be easily equipped with actuators, allowing for remote monitoring and control, which enhances operational precision and safety. Integration with smart systems facilitates predictive maintenance, minimizing downtime and extending the service life of the valves, thereby optimizing cost-efficiency. Importantly, environmental considerations are not neglected. The design of butterfly valve flange ends supports sustainable practices by minimizing energy consumption due to their efficient flow control systems. They also reduce the risk of leakage and spillage with their secure flange end connections, which is crucial in preventing environmental contamination particularly in chemical and petrochemical industries. In conclusion, the butterfly valve flange end stands as a testament to industrial ingenuity. Its evolution over the years continues to save costs, enhance efficiency, and foster innovation in fluid management systems. As industries strive for higher levels of operational excellence, the continued development and integration of advanced features in these valves ensure they remain at the forefront of industrial solutions, offering businesses a reliable and efficient tool to manage their fluid flow challenges. Through expert design and trusted performance, butterfly valve flange ends provide an indispensable component in the world of industrial automation and fluid control systems.

Trustworthiness of butterfly valve flange ends is amplified when considering manufacturers with a proven track record of delivering durable and reliable products. Reputable manufacturers invest in advanced manufacturing techniques and employ stringent quality control measures throughout the production process. This commitment to quality is reflected in the robustness and longevity of their valves, which perform consistently under harsh industrial conditions. Furthermore, ongoing field research and user feedback play significant roles in refining these products to better meet the evolving needs of industrial applications. The growing adoption of butterfly valve flange ends is also driven by their seamless integration with automated control systems. These valves can be easily equipped with actuators, allowing for remote monitoring and control, which enhances operational precision and safety. Integration with smart systems facilitates predictive maintenance, minimizing downtime and extending the service life of the valves, thereby optimizing cost-efficiency. Importantly, environmental considerations are not neglected. The design of butterfly valve flange ends supports sustainable practices by minimizing energy consumption due to their efficient flow control systems. They also reduce the risk of leakage and spillage with their secure flange end connections, which is crucial in preventing environmental contamination particularly in chemical and petrochemical industries. In conclusion, the butterfly valve flange end stands as a testament to industrial ingenuity. Its evolution over the years continues to save costs, enhance efficiency, and foster innovation in fluid management systems. As industries strive for higher levels of operational excellence, the continued development and integration of advanced features in these valves ensure they remain at the forefront of industrial solutions, offering businesses a reliable and efficient tool to manage their fluid flow challenges. Through expert design and trusted performance, butterfly valve flange ends provide an indispensable component in the world of industrial automation and fluid control systems.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024