10 月 . 06, 2024 13:45 Back to list

y type strainer

Understanding Y-Type Strainers A Comprehensive Overview

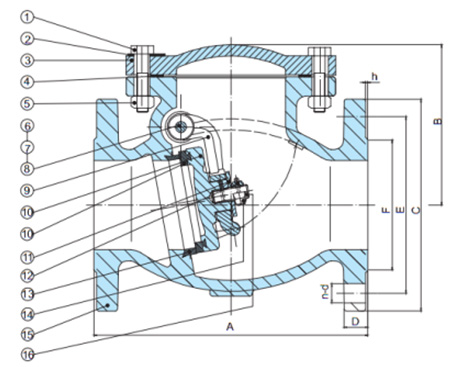

Y-type strainers are essential components in fluid systems, providing a reliable means to filter out particulates and impurities from liquids and gases. Designed in the shape of the letter “Y,” these strainers are particularly useful in piping systems where space may be limited, making them an ideal choice for various industrial applications, including water treatment, chemical processing, and HVAC systems.

The primary function of a Y-type strainer is to protect pumps, valves, and other equipment downstream from harmful particles that could cause damage or reduce efficiency. In a typical operation, fluid flows into the strainer, where it passes through a mesh or perforated screen that captures debris before the clean fluid continues along the pipeline. This process not only maintains the integrity of system components but also extends their operational life.

Design and Construction

Y-type strainers are typically constructed from materials such as stainless steel, carbon steel, or plastic, depending on the application and the fluid being filtered. The choice of material is vital, as it must withstand the chemical properties of the fluid and any potential pressure conditions. Standard mesh sizes can range from a fine 0.5 mm for filtration of small particulates to coarser options for larger debris.

The strainer's Y-shaped body allows for a more compact design compared to traditional basket strainers, while still enabling easy access for cleaning and maintenance. Most Y-type strainers are equipped with a blow-off or drain valve, allowing operators to quickly clean the mesh without removing the entire strainer from the pipeline. This feature enhances their practicality, especially in systems where downtime is costly.

Advantages of Y-Type Strainers

1. Space Efficiency The compact design of Y-type strainers makes them perfect for installations with limited space. Their configuration allows for installation in tight areas without sacrificing functionality or performance.

y type strainer

2. Cost-Effective Maintenance The ease of access for maintenance means that operators can perform regular cleaning without needing extensive downtime or labor costs, leading to reduced operational costs in the long run.

3. Versatility Y-type strainers can be used in various applications, from municipal water supply systems to chemical processing plants. They can effectively filter both hot and cold liquids, making them versatile for different industries.

4. Durability Constructed from robust materials, Y-type strainers can withstand harsh conditions, including high pressure and corrosive environments, ensuring long-term reliability and effectiveness.

Installation Considerations

When installing a Y-type strainer, it's essential to consider several factors. The strainer should be installed in the correct orientation, typically with the mesh screen horizontal, to ensure optimal performance. Additionally, the location of the strainer should allow for convenient access to the blow-off valve for regular maintenance.

Conclusion

In summary, Y-type strainers play a crucial role in enhancing the efficiency and longevity of fluid systems across a wide range of industries. Their space-saving design, easy maintenance, versatility, and durability make them a preferred choice for many applications. Understanding how Y-type strainers function and their installation requirements can help operators maintain optimal system performance while effectively managing impurities in fluid streams. Investing in quality strainers not only protects critical equipment but also contributes to smoother operations and reduced costs over time.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024