1 月 . 20, 2025 09:36 Back to list

y type strainer

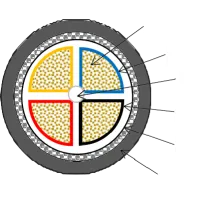

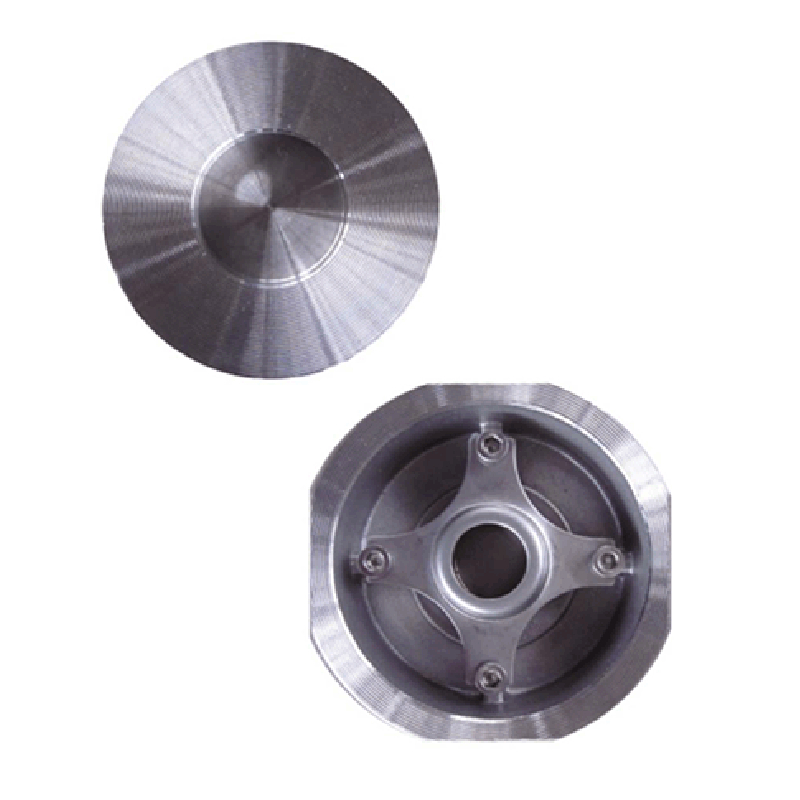

Y type strainers, critical components in numerous industrial applications, are designed to mechanically remove unwanted solids from liquid, gas, or steam lines using a wire mesh straining element. An effective practice in many industries, they offer protection for valuable equipment such as pumps, meters, and spray nozzles from potential damage caused by debris, thereby enhancing operational efficiency and longevity.

Real-world experience highlights the importance of regular maintenance schedules to ensure the longevity and efficiency of Y type strainers. Operators are advised to adhere to a systematic cleaning regimen, regularly checking the straining element for clogs and wear, which could impede the strainer's function. Implementing a proactive maintenance strategy not only extends the life of the strainer but also ensures the upstream equipment remains protected, maintaining the integrity of the entire system. The authoritative aspect of Y type strainers is evident in their conformity with industry standards and regulations. Leading manufacturers conduct rigorous testing and quality assurance to ensure that their strainers meet or exceed global standards, such as those set by ASME or API. These certifications provide end-users with confidence in the strainer's performance and reliability, reinforcing trust in the product. When integrating Y type strainers into a system, it is crucial to consult with experts who can evaluate the specific requirements of the application, recommend suitable configurations, and provide guidance on installation and maintenance best practices. This expertise ensures the strainer's maximum effectiveness and efficiency within the system. In terms of trustworthiness, investing in strainers from reputable manufacturers is prudent. Such companies offer warranties, customer support, and technical assistance, ensuring that users can depend on the product for long-term use. Establishing a relationship with a trustworthy supplier guarantees that in cases of unforeseen issues, support and solutions are readily available. Overall, Y type strainers represent a crucial investment in safeguarding sensitive and expensive equipment across various industries. Their design and functionality are supported by a long-standing history of performance and reliability. Employing them effectively requires a commitment to understanding their intricacies, maintaining them diligently, and collaborating with knowledgeable experts. Through integral application and upkeep, Y type strainers will continue to provide significant value and efficiency improvements in industrial operations.

Real-world experience highlights the importance of regular maintenance schedules to ensure the longevity and efficiency of Y type strainers. Operators are advised to adhere to a systematic cleaning regimen, regularly checking the straining element for clogs and wear, which could impede the strainer's function. Implementing a proactive maintenance strategy not only extends the life of the strainer but also ensures the upstream equipment remains protected, maintaining the integrity of the entire system. The authoritative aspect of Y type strainers is evident in their conformity with industry standards and regulations. Leading manufacturers conduct rigorous testing and quality assurance to ensure that their strainers meet or exceed global standards, such as those set by ASME or API. These certifications provide end-users with confidence in the strainer's performance and reliability, reinforcing trust in the product. When integrating Y type strainers into a system, it is crucial to consult with experts who can evaluate the specific requirements of the application, recommend suitable configurations, and provide guidance on installation and maintenance best practices. This expertise ensures the strainer's maximum effectiveness and efficiency within the system. In terms of trustworthiness, investing in strainers from reputable manufacturers is prudent. Such companies offer warranties, customer support, and technical assistance, ensuring that users can depend on the product for long-term use. Establishing a relationship with a trustworthy supplier guarantees that in cases of unforeseen issues, support and solutions are readily available. Overall, Y type strainers represent a crucial investment in safeguarding sensitive and expensive equipment across various industries. Their design and functionality are supported by a long-standing history of performance and reliability. Employing them effectively requires a commitment to understanding their intricacies, maintaining them diligently, and collaborating with knowledgeable experts. Through integral application and upkeep, Y type strainers will continue to provide significant value and efficiency improvements in industrial operations.

Share

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024