10 月 . 01, 2024 09:36 Back to list

Efficient Y Strainer Filters for Industrial Fluid Management and Protection

The Y Strainer Filter An Essential Component in Fluid Systems

In a world increasingly reliant on efficient fluid management systems, the Y strainer filter plays a critical role across various industries. This essential device is designed to protect pipelines, valves, pumps, and other equipment from debris and contaminants that can cause wear, clogging, and ultimately, system failures. Let's explore the functionality, design, applications, and benefits of Y strainer filters.

Design and Functionality

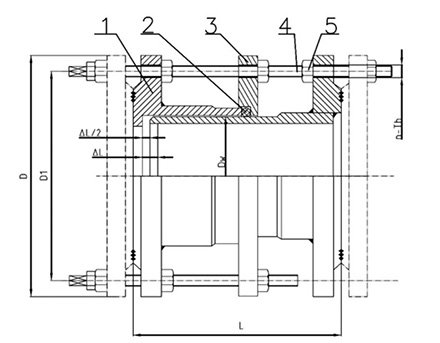

The Y strainer gets its name from its distinctive Y shape, which allows for easy installation in pipeline systems. Constructed typically from materials such as stainless steel, carbon steel, or plastic, the design facilitates the effective filtration of liquids and gases. Within this strainer, a mesh screen or perforated plate acts as the filtration medium, capturing particles while allowing the fluid to flow through.

When fluid enters the strainer, it flows into the wider end and passes through the filtration element. The design enables the passage of cleaner fluid while trapping unwanted debris, which is typically kept within the strainer body. The debris can then be removed through regular cleaning or backwashing, allowing for continuous operation without dismantling the system.

Applications of Y Strainer Filters

Y strainers are versatile components found in numerous applications. They are commonly used in

1. Water Treatment Facilities To ensure that only clean water enters the treatment process, protecting pumps and valves from sediment and larger particles. 2. Chemical Processing In industries where chemicals are handled, Y strainers prevent contamination of sensitive processes by filtering out unwanted materials. 3. HVAC Systems They ensure that cooling and heating systems operate efficiently by removing debris from the liquid refrigerants and water. 4. Food and Beverage Adherence to hygiene standards is crucial, and Y strainers help filter out impurities in the production processes, safeguarding product quality. 5. Oil and Gas Protecting equipment from particulates in crude oil and gas processing systems is vital, and Y strainers play a key role.

y strainer filter

Benefits of Using Y Strainer Filters

The advantages of integrating Y strainer filters into a fluid management system are significant

1. Protection By filtering out debris, Y strainers prevent damage to expensive equipment, such as pumps and valves, ensuring longevity and reliability. 2. Cost-Effectiveness Regular maintenance and operation costs are reduced because of fewer breakdowns and repairs, leading to significant savings in the long run.

3. Ease of Maintenance Y strainers are designed for easy access and cleaning. Many models allow for simple removal of the mesh screen for manual cleaning or replacement without the need to cut into the piping.

4. Versatility They can be used in a wide range of applications, making them suitable for diverse industries and processes.

5. Improved Efficiency A clean fluid system allows for improved flow rates and system pressure, enhancing overall operational efficiency.

Conclusion

Y strainer filters serve as a quintessential element in the maintenance and operation of various fluid management systems. Their ability to effectively capture and hold debris while allowing for smooth fluid passage makes them invaluable in protecting equipment and ensuring efficient operations in countless industrial applications. Given their numerous benefits and ease of maintenance, incorporating a Y strainer into any fluid system represents a proactive approach to system design and management. As industries continue to evolve and seek higher efficiencies, Y strainers will undoubtedly remain a fundamental part of fluid filtration strategies.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024