11 月 . 03, 2024 11:55 Back to list

y strainer ansi 150

Understanding Y Strainers and ANSI 150 Specifications

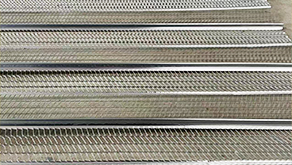

Y strainers are essential components in various piping systems, designed to filter out debris and particulates from fluid flow. They play a critical role in protecting equipment such as pumps, valves, and other machinery from damage caused by foreign particles. When discussing Y strainers, it is important to consider the ANSI 150 specifications, which define the pressure-temperature ratings and standards for flanged pipe fittings.

Understanding Y Strainers and ANSI 150 Specifications

ANSI, or the American National Standards Institute, plays a vital role in establishing engineering standards across various industries. The ANSI 150 specification refers specifically to flanged fittings that are designed to withstand certain pressure levels at specific temperatures. For example, an ANSI 150 Y strainer is built to handle pressures typically up to 150 psi (pounds per square inch) at a temperature range of up to 100°F (38°C). Depending on the material of the strainer, such as carbon steel, stainless steel, or bronze, the maximum temperature ratings may vary.

y strainer ansi 150

When selecting a Y strainer according to ANSI 150 specifications, it's crucial to consider factors such as the flow rate, the size of the particles to be filtered, and the type of fluid being processed. The dimensions of the Y strainer must also match the piping system to prevent flow problems and maintain efficient operation. Common sizes for ANSI 150 Y strainers range from 1 inch to 12 inches in diameter, allowing for flexibility in various system designs.

Installation of a Y strainer is relatively straightforward but requires careful attention to detail. The strainer should be positioned with the mesh screen oriented horizontally to facilitate cleaning and maintenance. Regular inspection is recommended to ensure that the straining element is not clogged, which can lead to pressure drops and reduced efficiency.

In conclusion, Y strainers conforming to ANSI 150 standards are essential for maintaining the integrity of fluid systems. By filtering out harmful particulates, these strainers help to prolong the operational life of crucial equipment. Engineers and system designers must carefully evaluate their specific requirements and choose the right Y strainer to ensure optimal performance. Proper implementation and maintenance of these strainers are integral to the smooth operation of any piping system.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024