10 月 . 31, 2024 08:11 Back to list

y strainer ansi 150

Understanding Y-Strainer ANSI 150 A Crucial Component in Fluid Systems

In the realm of fluid systems, maintaining optimal performance and system integrity is paramount. One essential component that aids in achieving this goal is the Y-strainer, specifically those designed according to the ANSI 150 standards. This article delves into the functionality, benefits, and critical applications of the Y-strainer in various industries.

What is a Y-Strainer?

A Y-strainer is a type of filtration device that is used to remove unwanted solid particles from a liquid or gas. It is named for its shape, resembling the letter Y. This design allows for the seamless integration of the strainer into pipeline systems while maintaining a low pressure drop. The strainer consists of a straining element housed in a valve body, and it is typically installed in horizontal or vertical pipelines.

ANSI 150 Standards

The ANSI (American National Standards Institute) 150 refers to a specific pressure rating and flange standard. Y-strainers meeting this specification are designed to handle a maximum pressure of 150 psi. The ANSI 150 standardization ensures that the strainer is compatible with a wide range of piping systems, allowing for easy integration and consistent performance across different setups. Moreover, ANSI standards help in maintaining quality, safety, and performance across various applications.

Benefits of Y-Strainers

1. Efficient Filtration Y-strainers are designed to effectively trap debris and particulates, preventing them from entering critical system components like pumps, valves, and nozzles. This helps in prolonging the life of these equipment and reducing maintenance costs.

2. Low Pressure Drop One of the key advantages of Y-strainers is their ability to maintain low pressure drops. This feature ensures that the flow rate within the system remains stable, which is crucial for processes relying on consistent fluid dynamics.

y strainer ansi 150

3. Ease of Maintenance Y-strainers come with removable straining elements, allowing for easy cleaning and maintenance. This feature ensures that operators can quickly access the strainer for inspections, reducing downtime and ensuring continuous operation.

4. Versatility These strainers are suitable for various applications, including water, steam, oil, and gas systems. Their ability to handle different types of fluids makes them a universally applicable solution in industries such as manufacturing, energy, and water treatment.

Applications of Y-Strainers

Y-strainers have widespread usage across various sectors

- Water Treatment In water treatment plants, Y-strainers are used to remove debris from water sources, ensuring the quality of treated water. - Chemical Processing In chemical manufacturing, Y-strainers protect sensitive equipment from solid contaminants, thus improving overall process efficiency.

- Oil and Gas In the oil and gas sector, these strainers are utilized to safeguard pipelines and equipment from particulate matter, ensuring safe and effective operations.

Conclusion

In summary, Y-strainers designed to ANSI 150 standards serve as a vital component in fluid systems, providing efficient filtration, low pressure drop, and ease of maintenance. Their versatility across various industries makes them an indispensable tool for maintaining system integrity and enhancing operational efficiency. Understanding the role of Y-strainers in your fluid system can lead to better performance and lower operational risks, ensuring that industries can operate smoothly and effectively.

Share

-

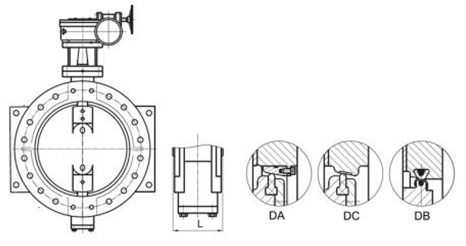

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024