2 月 . 15, 2025 13:40 Back to list

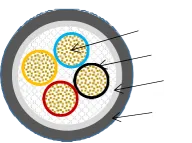

wire and cable factory

A wire and cable factory stands as a vital cornerstone in the industrial landscape, providing essential materials that power a myriad of sectors. From the intricacies of micro-electronics to the robust demands of heavy machinery, the products crafted within these factories are indispensable. Understanding the nuances of wire and cable manufacturing reveals a tapestry of expert engineering, sophisticated technology, and meticulous quality assurance processes that underpin their reliability and performance.

Trustworthiness is the hallmark of a premier wire and cable factory. It is built upon decades of dependable product delivery and customer satisfaction. Factories invest in advanced technologies like high-speed extrusion and automated spooling, which minimize human error and enhance product consistency. Consistent communication with clients from design conception through to delivery schedules fortifies buyer confidence and fosters long-term partnerships. Additionally, after-sales support, offering technical assistance and troubleshooting, are integral services that reinforce trust and ensure seamless operational continuity for customers. Moreover, real-world applications of these products provide testament to their efficacy. Electrical networks in urban infrastructures or the precision cables in medical devices depend heavily on the integrity of these components, making reliability non-negotiable. The wire and cable produced in these factories are often put to the ultimate test in harsh environmental conditions, such as extreme temperatures or high salinity, validating their design and resilience. In conclusion, the role of a wire and cable factory transcends mere production. It is a convergence of expertise, technological innovation, and an unwavering commitment to quality and customer satisfaction. The reliability of these industrial products reinforces how foundational this industry is to modern convenience and technological progression. For stakeholders, aligning with an esteemed manufacturer is paramount, ensuring that their projects are supported by components capable of enduring the rigors of time and operation, ultimately propelling advancements across various domains and industries.

Trustworthiness is the hallmark of a premier wire and cable factory. It is built upon decades of dependable product delivery and customer satisfaction. Factories invest in advanced technologies like high-speed extrusion and automated spooling, which minimize human error and enhance product consistency. Consistent communication with clients from design conception through to delivery schedules fortifies buyer confidence and fosters long-term partnerships. Additionally, after-sales support, offering technical assistance and troubleshooting, are integral services that reinforce trust and ensure seamless operational continuity for customers. Moreover, real-world applications of these products provide testament to their efficacy. Electrical networks in urban infrastructures or the precision cables in medical devices depend heavily on the integrity of these components, making reliability non-negotiable. The wire and cable produced in these factories are often put to the ultimate test in harsh environmental conditions, such as extreme temperatures or high salinity, validating their design and resilience. In conclusion, the role of a wire and cable factory transcends mere production. It is a convergence of expertise, technological innovation, and an unwavering commitment to quality and customer satisfaction. The reliability of these industrial products reinforces how foundational this industry is to modern convenience and technological progression. For stakeholders, aligning with an esteemed manufacturer is paramount, ensuring that their projects are supported by components capable of enduring the rigors of time and operation, ultimately propelling advancements across various domains and industries.

Share

Prev:

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024