10 月 . 08, 2024 18:53 Back to list

Exploring Wafer Style Silent Check Valves for Efficient Fluid Control

Wafer Type Silent Check Valve An Essential Component for Efficient Fluid Systems

In industrial applications, particularly in fluid control systems, the importance of reliable valves cannot be overstated. Among various types of valves, the wafer type silent check valve has gained significant popularity due to its compact design and efficient functionality. This article will explore the structure, benefits, and applications of wafer type silent check valves, shedding light on why they are a preferred choice in many industries.

Understanding Wafer Type Silent Check Valves

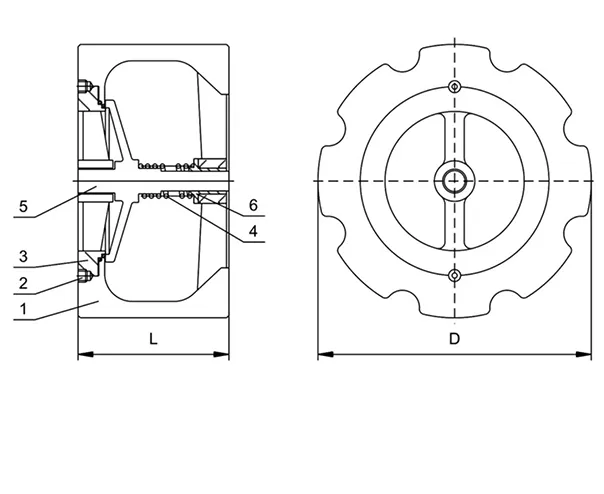

Wafer type silent check valves are specifically designed to allow fluid flow in one direction while preventing backflow. Unlike traditional swing check valves, which can create slamming noises due to rapid closure, silent check valves utilize a poppet mechanism that ensures a smoother operation. The term “wafer” refers to the valve’s slim profile, allowing it to be sandwiched between flanges in a pipeline. This design feature significantly reduces the overall weight and space required compared to other valve types.

Design Features

The key feature of a wafer type silent check valve is its internal mechanism. Typically, these valves consist of a body, a disc (or poppet), and a spring. The fluid flow lifts the disc, allowing it to open and pass through. When the flow stops or reverses, the spring gently closes the disc, preventing backflow. This design minimizes water hammer effects—an issue that can lead to piping damage and increased maintenance costs.

Manufacturers usually produce wafer type silent check valves in various materials, including stainless steel, cast iron, and bronze, to suit different environmental conditions and fluid applications. They also come in various sizes and pressure ratings, making them versatile for multiple uses.

Advantages of Wafer Type Silent Check Valves

1. Compact Design One of the most significant advantages of wafer type silent check valves is their compact form. Their low-profile design means that they require less space, making them ideal for environments where space is at a premium.

wafer type silent check valve

2. Reduced Noise As the name suggests, silent check valves operate quietly. The poppet’s smooth operation minimizes the risk of clattering noise during closure, contributing to a quieter working atmosphere, particularly in residential or sensitive environments.

3. Minimal Maintenance These valves are designed for durability and longevity. The straightforward design typically results in fewer parts that require maintenance, helping reduce operational costs over time.

4. High Efficiency Wafer type silent check valves maintain a streamlined flow, leading to better performance in fluid systems. Their ability to prevent backflow ensures that the system operates at optimal efficiency, reducing energy loss.

5. Ease of Installation The wafer design allows for easy installation between flanges, which can lead to improved workflow and reduced labor costs during the installation process.

Applications

Wafer type silent check valves are widely used across various industries, including

- Water and Wastewater Management They play a critical role in municipal water systems, preventing backflow and ensuring clean water distribution. - HVAC Systems In heating, ventilation, and air conditioning systems, these valves help maintain pressure and fluid flow efficiency. - Pumping Stations They are essential in ensuring that pumps operate correctly, preventing backflow that could damage the equipment. - Food and Beverage Industry Their hygienic design and material options make them suitable for applications in food processing and beverage production.

Conclusion

The wafer type silent check valve is an integral component in modern fluid systems, combining efficiency, reliability, and compactness. Understanding its benefits and applications enables industries to optimize their fluid control measures, ultimately leading to improved performance and reduced operational costs. As technology advances and industrial processes evolve, the demand for such innovative solutions will continue to grow, solidifying the wafer type silent check valve's place in the industry.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024