1 月 . 19, 2025 04:44 Back to list

Metal Braided Screen/With Monitoring Core/Portable Mining Rubber Cable

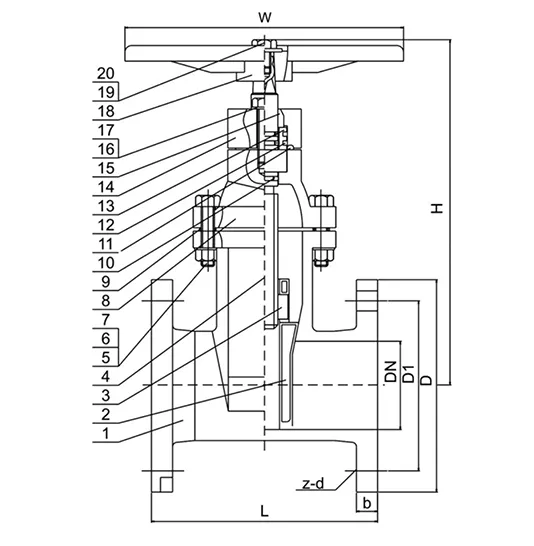

The wafer type silent check valve is an integral component in modern fluid systems, known for its unique design and operational efficiency. Designed to prevent backflow and eliminate water hammer, this valve is a staple in industries where fluid regulation and control are paramount. Its compact, wafer-style body makes it an ideal choice for systems requiring space efficiency and reliability without compromising performance.

Trustworthiness in engineering solutions is built through rigorous performance consistency. The wafer type silent check valve, thanks to its robust design, offers a reliable solution to prevent back flow, which can otherwise lead to equipment damage, increased operating costs, and safety hazards. Users have reported enhanced system reliability and lower maintenance demands, showcasing the valve's credibility in demanding scenarios. This trust extends particularly to sectors where the safety of operations is non-negotiable. Customers seeking to invest in wafer type silent check valves must consider a few key factors – maximum working pressure, material compatibility in relation to their fluid, and the specific parameters of their system. Choosing the correct valve not only fulfills operational needs but also enhances overall energy efficiency, by minimizing flow resistance and pressure drops. This optimization is fundamental to achieving sustainable and cost-effective system management. In conclusion, the wafer type silent check valve is more than just a component—it's a testament to advanced engineering and careful consideration toward performance excellence. Its features underscore an engineering marvel that marries practicality with innovation, benefiting diverse industrial needs. When chosen and implemented correctly, these valves offer an unrivaled, authoritative solution that guarantees system integrity, operational quietness, and long-term reliability, hallmarks of excellent engineering and superior product design.

Trustworthiness in engineering solutions is built through rigorous performance consistency. The wafer type silent check valve, thanks to its robust design, offers a reliable solution to prevent back flow, which can otherwise lead to equipment damage, increased operating costs, and safety hazards. Users have reported enhanced system reliability and lower maintenance demands, showcasing the valve's credibility in demanding scenarios. This trust extends particularly to sectors where the safety of operations is non-negotiable. Customers seeking to invest in wafer type silent check valves must consider a few key factors – maximum working pressure, material compatibility in relation to their fluid, and the specific parameters of their system. Choosing the correct valve not only fulfills operational needs but also enhances overall energy efficiency, by minimizing flow resistance and pressure drops. This optimization is fundamental to achieving sustainable and cost-effective system management. In conclusion, the wafer type silent check valve is more than just a component—it's a testament to advanced engineering and careful consideration toward performance excellence. Its features underscore an engineering marvel that marries practicality with innovation, benefiting diverse industrial needs. When chosen and implemented correctly, these valves offer an unrivaled, authoritative solution that guarantees system integrity, operational quietness, and long-term reliability, hallmarks of excellent engineering and superior product design.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024