10 月 . 10, 2024 17:07 Back to list

wafer type butterfly valve price

Understanding Wafer Type Butterfly Valve Prices

The wafer type butterfly valve is a crucial component in many industrial and commercial applications, providing an efficient means of controlling fluid flow. As industries evolve, so do the technologies that support them, leading to variations in the types, designs, and prices of these valves. Understanding the factors that influence the price of wafer type butterfly valves is essential for making informed purchasing decisions.

What is a Wafer Type Butterfly Valve?

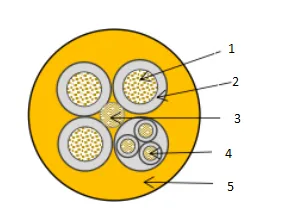

A wafer type butterfly valve is a quarter-turn valve that uses a rotating disc to regulate fluid flow. It is installed between two flanges and is designed to fit within a pipe system without requiring additional flanged connections. This compact design significantly reduces the overall weight and space requirements, making it ideal for various applications, including water treatment, HVAC systems, and chemical processing.

Factors Influencing Price

1. Material Composition The material from which the valve is made considerably affects its price. Common materials include cast iron, stainless steel, and PVC. Generally, stainless steel valves, known for their corrosion resistance and durability, tend to be more expensive than their cast iron or plastic counterparts. The choice of material will depend on the specific application and the fluid being handled.

2. Size and Dimension The size of the valve directly correlates to its price. Larger valves, which can handle higher volumes of flow, typically cost more due to the increased material used and the complexity of manufacturing. When selecting a valve, it is essential to consider not only the size that meets your needs but also one that aligns with your budget.

wafer type butterfly valve price

3. Pressure Rating Butterfly valves are rated for different pressure classes, often measured in pounds per square inch (PSI). Valves that can handle higher pressure ratings usually come with increased construction strength, which also contributes to a higher price. It is vital to choose a valve that suits the specific pressure requirements of your application.

4. Brand and Manufacturer Just like any other product, the brand can play a significant role in pricing. Established manufacturers with a reputation for quality and reliability often charge a premium for their products. It is important to consider the balance between cost and quality when choosing a brand. Cheaper options may save money upfront but could lead to higher maintenance costs and potential downtime in the long run.

5. Technology and Design Advanced technologies in valve design can also impact prices. Features such as improved sealing capabilities, reduced torque specifications, and enhanced flow characteristics often come at a higher cost. Manufacturers that invest in research and development to bring innovative features to their products typically reflect that investment in their pricing.

6. Market Demand and Economic Factors Like many commodities, the price of wafer type butterfly valves can be influenced by market demand and economic conditions. Fluctuations in the raw materials market, changes in manufacturing costs, and shifts in demand due to industry trends can lead to variations in the pricing of these valves.

Conclusion

When considering the purchase of wafer type butterfly valves, it is essential to take a holistic approach that weighs the factors affecting price against the specific needs of your application. Understanding the influences behind pricing—such as material, size, pressure ratings, brand reliability, advanced technology, and overall market conditions—will empower you to make educated decisions.

Investing in high-quality wafer type butterfly valves may require a higher initial outlay; however, the long-term benefits of reliability, efficiency, and reduced maintenance costs often justify the expense. By carefully examining your requirements and budget, you can select the right valve that meets both your operational needs and financial constraints, ensuring a successful implementation in your fluid management system.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024