10 月 . 11, 2024 01:01 Back to list

wafer type butterfly valve flange

Understanding Wafer Type Butterfly Valve Flanges

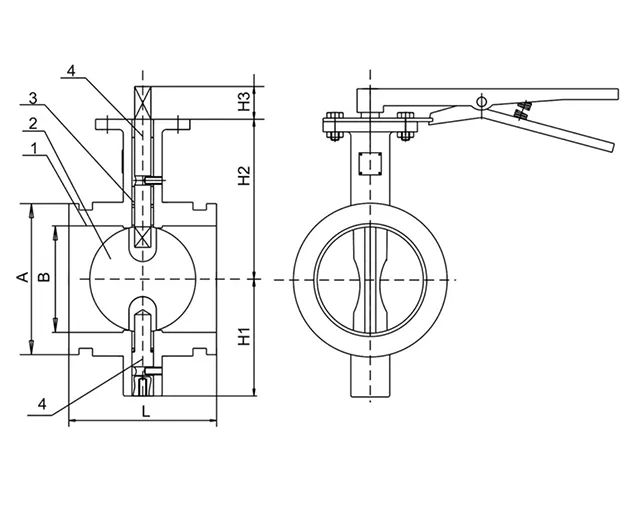

Butterfly valves are essential components in various industrial applications, particularly in controlling the flow of fluids. Among the different types of butterfly valves, the wafer type stands out due to its compact design and efficient performance. A crucial aspect of wafer type butterfly valves is the flange, which plays a significant role in the installation and overall functionality of the valve.

Understanding Wafer Type Butterfly Valve Flanges

Flanges are critical for creating secure connections between the valve and the piping system. For wafer type butterfly valves, standard flanges such as ANSI, DIN, or JIS are often used, ensuring compatibility with existing piping infrastructure. The flange type affects not only the assembly but also the performance capabilities of the valve. It’s essential to choose the correct flange to achieve optimal sealing and prevent leaks during operation.

wafer type butterfly valve flange

In terms of material selection, wafer type butterfly valves can be made from various materials, including cast iron, stainless steel, and PVC. The choice of material often depends on the application, with considerations for the type of fluid handled, temperature, and pressure requirements. For example, stainless steel valves are preferred in corrosive environments due to their superior resistance to chemical degradation.

The installation of wafer type butterfly valves is relatively straightforward. The valve is sandwiched between two flanges and secured with bolts. This configuration allows for easy maintenance and replacement while ensuring a tight seal throughout the valve's operational life. Proper alignment during installation is critical to prevent undue stress on the valve disc, which could lead to premature wear or failure.

In summary, wafer type butterfly valves with flanges offer versatility and efficiency for fluid control in a wide range of industries. Their lightweight design, ease of installation, and robust performance make them a popular choice among engineers and maintenance professionals. Selecting the appropriate flange type and ensuring quality installation are paramount for achieving optimal performance and longevity in any piping system. As industries continue to evolve, the demand for reliable and efficient flow control solutions like wafer type butterfly valves will undoubtedly grow.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024