3 月 . 05, 2025 01:34 Back to list

wafer type butterfly valve dimension

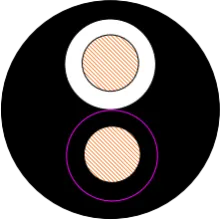

Butterfly valves, particularly wafer type butterfly valves, are an indispensable component in various industrial applications due to their compact design and efficient performance in controlling flow. Ensuring optimal functionality requires a clear understanding of their dimensions, which respectively affect installation, operation, and maintenance. This article delves into the critical dimensions of wafer type butterfly valves, emphasizing their practical applications in the industry.

The bolt circle diameter (BCD) of the valve is another critical dimension, impacting how the valve is mounted between flanges. Correct BCD selection ensures that the valve remains securely attached and aligned. Improper BCD can lead to leakage or failure of the entire valve system. Thus, ensuring compatibility between the BCD of the wafer valve and the flange specifications is paramount. Material choice for wafer type butterfly valves also hinges on understanding their dimensions. The materials used, whether they be steel, cast iron, or PVC, must align with the application needs while supporting the structural integrity defined by the valve dimensions. Moreover, selecting the right material helps prevent issues such as corrosion, which can compromise valve dimensions and lead to operational failures. Achieving the perfect balance among dimensions requires expertise and an in-depth understanding of the operational environment. Consulting with manufacturers and leveraging standardized guidelines often results in better decision-making. Engineers must consider the interplay between dimensions and the specific conditions under which the valve will operate, such as temperature, fluid type, and pressure. The significance of wafer type butterfly valve dimensions cannot be overstated. These dimensions ensure appropriate integration into piping systems, impacting the valve's performance, efficiency, and lifespan. Selecting the correct dimensions requires an amalgamation of practical experience and technical knowledge, ensuring that wafer type butterfly valves not only meet the installation requirements but also operate optimally throughout their service life. Consequently, engineers should meticulously evaluate these parameters while considering future maintenance requirements and potential system upgrades. This holistic approach not only enhances the reliability of the wafer type butterfly valve but also contributes to the overall efficiency and safety of industrial operations.

The bolt circle diameter (BCD) of the valve is another critical dimension, impacting how the valve is mounted between flanges. Correct BCD selection ensures that the valve remains securely attached and aligned. Improper BCD can lead to leakage or failure of the entire valve system. Thus, ensuring compatibility between the BCD of the wafer valve and the flange specifications is paramount. Material choice for wafer type butterfly valves also hinges on understanding their dimensions. The materials used, whether they be steel, cast iron, or PVC, must align with the application needs while supporting the structural integrity defined by the valve dimensions. Moreover, selecting the right material helps prevent issues such as corrosion, which can compromise valve dimensions and lead to operational failures. Achieving the perfect balance among dimensions requires expertise and an in-depth understanding of the operational environment. Consulting with manufacturers and leveraging standardized guidelines often results in better decision-making. Engineers must consider the interplay between dimensions and the specific conditions under which the valve will operate, such as temperature, fluid type, and pressure. The significance of wafer type butterfly valve dimensions cannot be overstated. These dimensions ensure appropriate integration into piping systems, impacting the valve's performance, efficiency, and lifespan. Selecting the correct dimensions requires an amalgamation of practical experience and technical knowledge, ensuring that wafer type butterfly valves not only meet the installation requirements but also operate optimally throughout their service life. Consequently, engineers should meticulously evaluate these parameters while considering future maintenance requirements and potential system upgrades. This holistic approach not only enhances the reliability of the wafer type butterfly valve but also contributes to the overall efficiency and safety of industrial operations.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024