2 月 . 14, 2025 23:40 Back to list

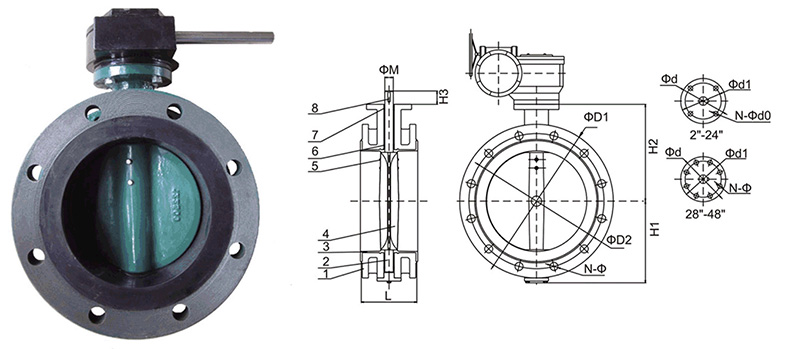

wafer type butterfly valve dimension

Selecting the right wafer type butterfly valve is essential for ensuring optimal performance in fluid control systems, be it in an industrial or domestic setting. Understanding the dimensions of these valves can significantly affect their functionality and suitability for specific applications.

Wafer type butterfly valves are versatile, serving in various sectors including water treatment, food and beverage, and chemical processing. Each sector may have specific requirements for valve dimensions to achieve the desired performance levels. For instance, food and beverage industries may require valves with more precise tolerances to avoid contamination and ensure hygiene. When choosing the valve, referencing dimensional standards like ISO, API, or ASME can provide a benchmark for ensuring the valve meets certain quality and performance criteria. An industry expert can assist in interpreting these standards to guarantee that the selected valve dimension will integrate flawlessly into existing systems. Adherence to these dimensions not only assures optimal system performance but also enhances safety through properly fitted components that reduce the risk of leaks or mechanical failures. Furthermore, correctly fitted valves minimize maintenance requirements and promote longevity, proving cost-effective in the long run. Trustworthiness in selecting a valve vendor cannot be overstated. Reputable manufacturers offer detailed specifications and support, ensuring that every aspect of the valve, from dimensions to material, meets the highest standards. They often provide certificates of compliance and extensive testing data to reinforce the reliability of their products. In conclusion, understanding the dimensions of wafer type butterfly valves is pivotal in achieving efficient and reliable fluid control. These dimensions directly affect flow rate, compatibility, and operational integrity. Therefore, always engage with experts and trusted manufacturers when making selections, to ensure the valves meet the specific needs of your application while adhering to industry standards for safety and performance.

Wafer type butterfly valves are versatile, serving in various sectors including water treatment, food and beverage, and chemical processing. Each sector may have specific requirements for valve dimensions to achieve the desired performance levels. For instance, food and beverage industries may require valves with more precise tolerances to avoid contamination and ensure hygiene. When choosing the valve, referencing dimensional standards like ISO, API, or ASME can provide a benchmark for ensuring the valve meets certain quality and performance criteria. An industry expert can assist in interpreting these standards to guarantee that the selected valve dimension will integrate flawlessly into existing systems. Adherence to these dimensions not only assures optimal system performance but also enhances safety through properly fitted components that reduce the risk of leaks or mechanical failures. Furthermore, correctly fitted valves minimize maintenance requirements and promote longevity, proving cost-effective in the long run. Trustworthiness in selecting a valve vendor cannot be overstated. Reputable manufacturers offer detailed specifications and support, ensuring that every aspect of the valve, from dimensions to material, meets the highest standards. They often provide certificates of compliance and extensive testing data to reinforce the reliability of their products. In conclusion, understanding the dimensions of wafer type butterfly valves is pivotal in achieving efficient and reliable fluid control. These dimensions directly affect flow rate, compatibility, and operational integrity. Therefore, always engage with experts and trusted manufacturers when making selections, to ensure the valves meet the specific needs of your application while adhering to industry standards for safety and performance.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024