10 月 . 30, 2024 19:16 Back to list

wafer type butterfly valve

Understanding Wafer Type Butterfly Valves

Wafer type butterfly valves are a crucial component in various industrial applications, serving as a reliable solution for regulating and controlling the flow of fluids in pipelines. Their design combines efficiency, low weight, and easy installation, making them popular in several sectors, including water treatment, chemical processing, and HVAC systems.

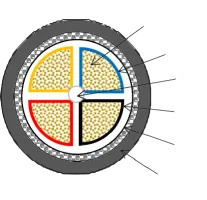

At the core of the wafer type butterfly valve is its simple yet effective mechanism. These valves consist of a circular disc or vane that rotates around a central axis. When the valve is in the closed position, the disc seals tightly against a resilient seat, preventing any fluid flow. Conversely, when the valve is opened, the disc rotates parallel to the fluid flow, allowing for maximum flow passage. This quarter-turn operation significantly reduces the time required to open or close the valve compared to traditional gate or globe valves.

One of the most significant advantages of wafer type butterfly valves is their space-saving design. Unlike other valve types, wafer valves do not require additional space for flanges and can be easily installed between two flanges. This feature makes them particularly useful in applications with limited space. Additionally, their lightweight design facilitates easier handling and installation, reducing labor costs and minimizing the risk of injury during the installation process.

wafer type butterfly valve

Durability and versatility are also key characteristics of wafer type butterfly valves

. They can be manufactured from various materials, such as cast iron, stainless steel, and plastic, allowing for use in diverse environments and applications. Whether dealing with corrosive chemicals or hot water, there is a wafer valve designed to meet the specific operational demands of the application.Another important aspect to consider is the valve's sealing performance. Most wafer type butterfly valves employ a rubber or elastomeric seat that enhances sealing capabilities and extends the valve's lifespan. This feature is particularly beneficial in applications where tight shut-off is essential, as it minimizes leakage and ensures efficient operation.

Moreover, wafer type butterfly valves are suitable for both throttling and on-off control, making them adaptable to varying operational requirements. They can be utilized in systems requiring precise flow control, as well as those needing quick isolation of flow.

In conclusion, wafer type butterfly valves offer numerous advantages, including a compact design, ease of installation, and versatility in material selection. These characteristics, combined with their durability and effective sealing capabilities, make them an excellent choice for various industrial applications. As industries continue to seek efficient and reliable solutions for fluid control, the wafer type butterfly valve will undoubtedly remain a prominent choice in the market.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024