9 月 . 25, 2024 18:51 Back to list

wafer type butterfly check valve

Wafer Type Butterfly Check Valve An Overview

In industrial applications, efficient fluid control is indispensable for maintaining system integrity and performance. One of the pivotal elements in fluid management is the valve, and among the various types available, the wafer type butterfly check valve has emerged as a popular choice due to its unique design and functional benefits.

What is a Wafer Type Butterfly Check Valve?

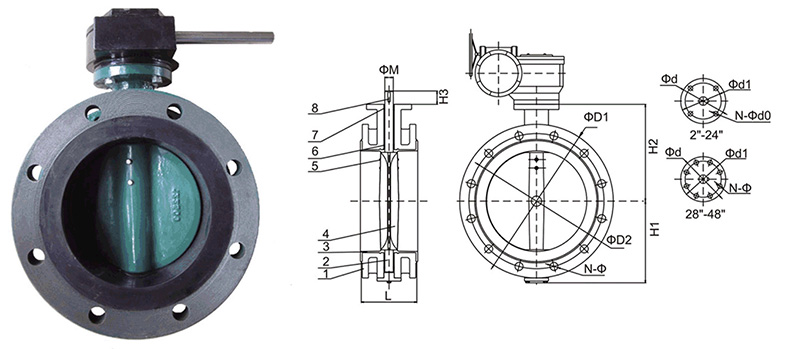

A wafer type butterfly check valve is a specialized valve that allows for one-directional fluid flow while preventing backflow. This is crucial in various systems where back pressure can cause damage or inefficiencies. Unlike traditional check valves, which can be bulkier and require more space, the wafer type valve is designed to be sandwiched between two flanges, leading to a more compact and lightweight profile.

The construction of a wafer type butterfly check valve consists of a disc, which pivots on a shaft. When the flow is in the designated direction, the disc remains open, allowing fluid to pass through. Conversely, when there is a backflow, the disc moves to a closed position, creating a seal that prevents any reverse flow. This mechanism not only ensures efficiency but also enhances safety in various applications.

Advantages of Wafer Type Butterfly Check Valves

One of the primary advantages of wafer type butterfly check valves is their space-saving design. Since they are smaller and lighter than traditional valves, they are particularly suitable for installations where space is at a premium. Their design also allows for easy installation between two pipeline flanges, reducing the need for additional fittings.

wafer type butterfly check valve

Moreover, these valves are known for their low-pressure drop characteristics. Because of their streamlined flow path, they do not impose significant resistance to fluid flow, making them ideal for applications that require high flow rates. This feature contributes to lower energy consumption, resulting in operational cost savings over time.

Another notable benefit is the versatility of materials used in the manufacturing of wafer type butterfly check valves. They can be constructed from a variety of materials, including stainless steel, ductile iron, and plastic, which makes them suitable for different media, including water, oil, and corrosive substances.

Applications of Wafer Type Butterfly Check Valves

The wafer type butterfly check valve finds applications across diverse industries. In water treatment facilities, they are employed to prevent backflow in water distribution lines. In the chemical processing industry, they are used to safeguard systems from reverse flow of hazardous substances. They are also prevalent in HVAC systems, mining, and oil and gas industries, underscoring their versatility and reliability.

Conclusion

In conclusion, the wafer type butterfly check valve is an essential component for effective fluid control in various industries. Its compact design, low-pressure drop, and versatility in materials make it an attractive choice for engineers and system designers. As industries continue to evolve and seek efficient solutions, the wafer type butterfly check valve stands out as a reliable option for ensuring fluid integrity and enhancing system performance across a multitude of applications.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024