10 月 . 06, 2024 04:31 Back to list

wafer butterfly valve factory

The Importance of the Wafer Butterfly Valve in Modern Industrial Applications

In the ever-evolving landscape of industrial technology, valve systems play a crucial role in controlling the flow of fluids and gases within various applications. Among the wide array of valve options available, the wafer butterfly valve has emerged as a favored choice due to its unique design and advantages in efficiency and space-saving capabilities. In this article, we will explore the features and benefits of wafer butterfly valves, along with insights into their manufacturing processes and applications across different industries.

Understanding the Wafer Butterfly Valve

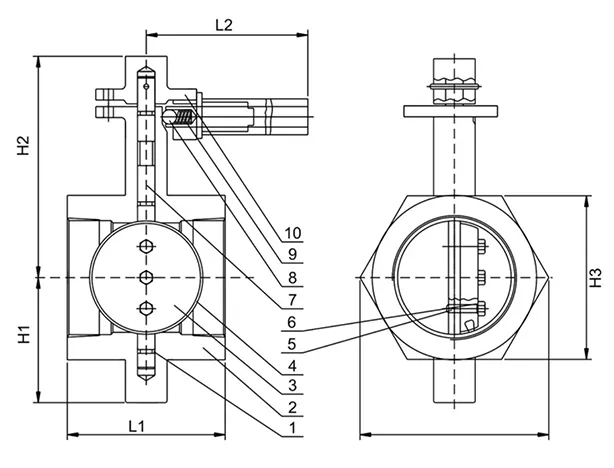

The wafer butterfly valve is a type of quarter-turn valve that consists of a rotating disc which regulates flow. The valve is mounted between two flanges and is designed to be lightweight and compact. This design makes it ideal for installations where space is limited. The central disc is positioned in line with the flow; when the valve is closed, the disc is perpendicular to the flow direction, effectively blocking it. When the valve is open, the disc rotates a quarter turn and allows fluid to pass through with minimal resistance.

Key Features and Advantages

One of the primary advantages of wafer butterfly valves is their ease of installation and maintenance. Unlike traditional gate or globe valves, which often require extensive piping modifications, the wafer design allows for quick and simple installation between existing flanges. This not only saves time but also reduces labor costs, making wafer butterfly valves a cost-effective choice for many applications.

Furthermore, wafer butterfly valves are renowned for their excellent flow characteristics. The streamlined design of the disc significantly reduces pressure drops compared to other valve types. This feature is particularly beneficial in systems where maintaining optimal flow rates is crucial, such as in water treatment facilities, chemical processing plants, and HVAC systems.

Another significant advantage is their versatility. Wafer butterfly valves can handle a wide range of substances, including liquids, gases, and slurries. They are available in various materials—such as stainless steel, cast iron, and plastic—to accommodate different environmental conditions and pressures. This adaptability ensures that wafer butterfly valves can be tailored to meet the specific needs of diverse industrial applications.

Manufacturing Process of Wafer Butterfly Valves

wafer butterfly valve factory

The production of wafer butterfly valves involves several key steps, each essential to ensuring performance and reliability. Firstly, the selection of raw materials is critical. High-quality materials are chosen based on the intended application, taking into consideration factors such as temperature, pressure, and the nature of the fluid being controlled.

Once the materials are selected, the manufacturing process begins with casting or machining components like the valve body, disc, and seat. Advanced manufacturing technologies, such as CNC machining and automated welding, are employed to create precise and durable components. These techniques not only enhance the quality of the valves but also improve production efficiency.

After fabricating the components, they go through rigorous testing to ensure they meet industry standards and specifications. This includes pressure testing, leak testing, and operational testing. Quality control is paramount in the manufacturing process, as it ensures that each valve can operate seamlessly under the conditions for which it was designed.

Applications in Various Industries

The versatility of wafer butterfly valves has led to their widespread adoption across numerous industries. In the water and wastewater sector, they are commonly used for flow regulation and isolation in pipelines. The food and beverage industry also utilizes these valves for their hygienic properties, ensuring minimal contamination risk during processing.

In the chemical and petrochemical industries, wafer butterfly valves provide reliable on/off control for corrosive materials. Additionally, they are employed in the HVAC sector to control airflow and facilitate temperature regulation.

Conclusion

Wafer butterfly valves stand out as an essential component in modern industrial applications. Their compact design, efficiency, and versatility make them exceptionally valuable across various sectors. As industries continue to seek advanced solutions for fluid control, the wafer butterfly valve's role will undoubtedly become more significant. Understanding their features, manufacturing processes, and applications helps stakeholders make informed decisions that enhance operational efficiency and reliability. In a world where every drop counts, embracing the benefits of wafer butterfly valves can lead to substantial improvements in process management and resource conservation.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024