12 月 . 05, 2024 19:38 Back to list

Understanding the Functionality and Design of Wafer Butterfly Valves in Fluid Control Systems

The Wafer Butterfly Valve A Comprehensive Overview

The wafer butterfly valve is a widely used device in various industrial applications due to its simple yet effective design. This type of valve is essential for managing the flow of liquids and gases in piping systems. Its compact structure, lightweight characteristics, and cost-effectiveness make it a popular choice for many engineers and operators.

Structure and Design

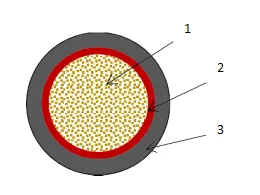

The wafer butterfly valve consists of a circular disc that pivots on a shaft. The disc is located in the center of the valve body, which is typically made of durable materials such as cast iron, stainless steel, or plastic, depending on the application and operating environment. The valve is designed to be installed between two flanges, which is where the term wafer comes from, emphasizing its flat profile. This design allows for easy installation and maintenance, making it an attractive option for various industries.

Functionality

The primary function of a wafer butterfly valve is to control the flow of fluid within a pipeline. The valve operates by rotating the disc 90 degrees to either fully open or fully close the flow. When the valve is open, the disc is parallel to the flow, allowing for minimal resistance and maximum flow capacity. Conversely, when fully closed, the disc creates a tight seal against the valve body, preventing any leakage. This simple mechanism enables quick operation and rapid response to flow changes.

Advantages

wafer butterfly valve

One of the most significant advantages of the wafer butterfly valve is its compactness. Compared to other valve types, such as gate or globe valves, the wafer design saves space within piping systems. This feature is particularly beneficial in situations where space is at a premium. Additionally, wafer butterfly valves are lightweight, leading to reduced installation and support costs.

Another notable benefit is the ease of operation. Wafer butterfly valves can be operated manually, mechanically, or through automated systems, making them versatile for various setups. Their straightforward design allows for easy maintenance, which translates to minimized downtime and reduced operational costs.

Applications

Wafer butterfly valves are utilized in numerous applications across different industries, including water treatment, chemical processing, HVAC systems, and food and beverage processing. Their ability to handle various types of fluids, from gases to slurries, makes them suitable for a plethora of environments. Furthermore, they can be engineered to withstand extreme pressures and temperatures, adding to their adaptability.

In the water treatment industry, wafer butterfly valves play a crucial role in the regulation of flow rates and pressure control. In HVAC systems, they assist in optimizing air circulation, allowing for efficient climate control. The food and beverage industry also benefits from these valves due to their hygienic designs, ensuring that the products remain uncontaminated during processing and transport.

Conclusion

The wafer butterfly valve is an essential component in modern piping systems, offering a combination of efficiency, space-saving design, and reliability. Its ability to facilitate the control of liquids and gases across various industries demonstrates its versatility and adaptability. As industries continue to evolve, the importance of effective flow management devices like wafer butterfly valves cannot be overstated. Their ongoing development and refinement will ensure that they remain integral to efficient industrial processes for years to come. With their numerous advantages, it's no surprise that wafer butterfly valves are a preferred choice among engineers and operators seeking dependable and efficient flow control solutions.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024