10 月 . 02, 2024 07:48 Back to list

Wafer and Lugged Butterfly Valve Options for Optimal Flow Control Solutions

Understanding Wafer and Lugged Butterfly Valves A Comprehensive Overview

Butterfly valves are essential components in various industrial applications, primarily used to regulate or isolate the flow of fluid in pipelines. Among the different types of butterfly valves available, wafer and lugged designs are particularly popular due to their unique features and advantages. This article delves into the characteristics, applications, and benefits of wafer and lugged butterfly valves, providing a comprehensive understanding of their importance in fluid management.

What are Wafer and Lugged Butterfly Valves?

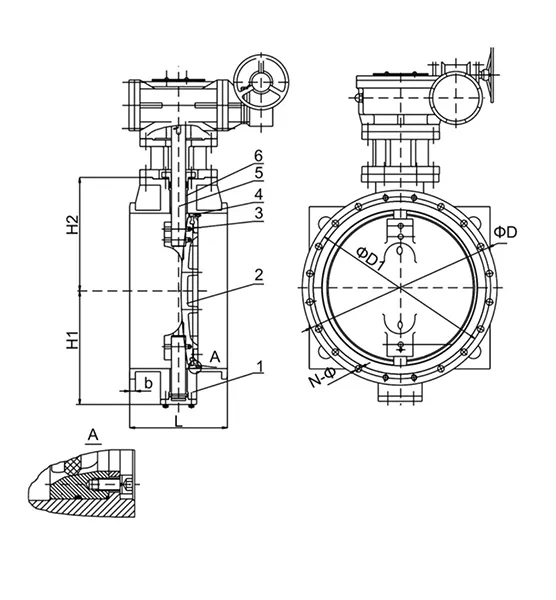

Butterfly valves operate using a rotating disk to control fluid flow. The disk is mounted on a shaft and pivots to either allow or block the flow through the pipeline. The primary distinction between wafer and lugged butterfly valves lies in their mounting configurations.

1. Wafer Butterfly Valves Wafer butterfly valves are designed for easy installation between two flanges. They have a compact, lightweight construction that allows them to occupy less space in the pipeline. This design is especially advantageous in tight installations where space is limited. Wafer valves do not have protruding lugs, which gives them a seamless and low-profile appearance.

2. Lugged Butterfly Valves In contrast, lugged butterfly valves feature threaded lugs on the body, allowing them to be bolted directly to the flanges of the adjacent piping systems. This design provides greater flexibility in installation and maintenance, as the valve can be removed without having to dismantle the entire pipeline. Lugged designs are often used in systems where frequent maintenance or replacement is anticipated.

Applications of Wafer and Lugged Butterfly Valves

Both wafer and lugged butterfly valves find applications across various industries, including

wafer and lugged butterfly valve

- Water Treatment Plants These valves play a critical role in controlling the flow of water and sewage in treatment facilities. - HVAC Systems Butterfly valves are used in heating, ventilation, and air conditioning systems to regulate airflow and maintain temperature control. - Chemical Processing The ability to handle corrosive fluids makes butterfly valves ideal for chemical manufacturing processes. - Food and Beverage Industry Sanitary models of butterfly valves are employed to ensure the safe and hygienic handling of food products.

Advantages of Wafer and Lugged Butterfly Valves

Both designs come with their unique advantages based on installation requirements and operational demands.

Advantages of Wafer Butterfly Valves - Space Efficiency Their compact design allows for more efficient use of space in piping layouts. - Cost-Effective Generally, wafer valves are less expensive than lugged valves, making them a cost-effective choice for many applications. - Reduced Weight The lightweight nature of wafer valves eases the burden on supporting structures and reduces shipping costs.

Advantages of Lugged Butterfly Valves - Ease of Maintenance The ability to replace or maintain the valve without disconnecting the entire piping system saves time and labor costs. - Versatility These valves can be used in systems that may experience fluctuating pressure conditions. - Robustness The bolted connection provides a sturdy setup, making lugged valves suitable for more demanding applications.

Conclusion

In summary, wafer and lugged butterfly valves are integral components in the management of fluid flows in various industrial applications. While wafer valves offer space-saving and cost-efficient solutions, lugged valves provide ease of maintenance and versatility in installation. Understanding the unique features and benefits of each design allows engineers and procurement specialists to make informed decisions based on the specific needs of their applications. Ultimately, selecting the right type of butterfly valve can lead to enhanced operational efficiency, cost savings, and improved reliability in fluid control systems. As industries continue to evolve, the demand for reliable valve solutions like wafer and lugged butterfly valves will remain critical in optimizing performance and ensuring safety in fluid handling processes.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024