9 月 . 10, 2024 16:55 Back to list

wafer butterfly valve manufacturers

The Impact of Wafer Butterfly Valve Manufacturers on Industrial Applications

In the realm of industrial applications, the significance of valves cannot be overstated, with wafer butterfly valves being among the most widely used. These innovative components are essential for regulating flow in various systems across industries such as water treatment, HVAC, and chemical processing. With the increasing demand for efficient flow control solutions, wafer butterfly valve manufacturers are playing a pivotal role in shaping the landscape of industrial operations.

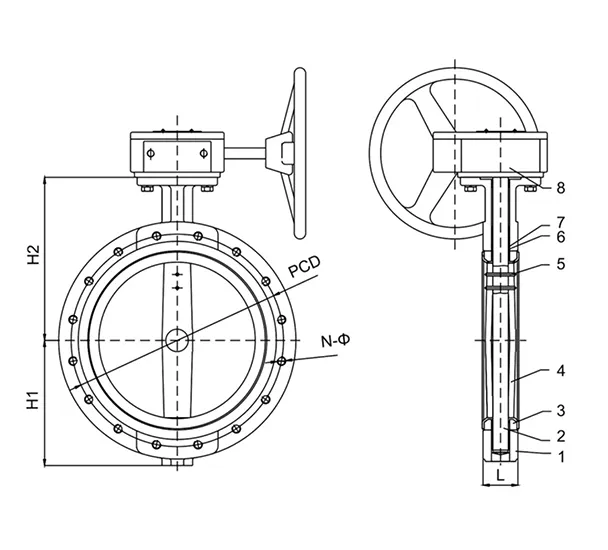

Wafer butterfly valves are designed to be lightweight and compact, making them ideal for tight spaces and environments where traditional valves may be cumbersome. Their construction includes a disc that rotates around a central axis, allowing for quick opening and closing. This design results in low pressure drops and minimal turbulence, promoting energy efficiency in flow systems. As industries strive for sustainability and cost-effectiveness, the demand for such efficient solutions continues to rise.

Manufacturers of wafer butterfly valves are continuously innovating to enhance the functionality and durability of their products. Advanced materials, such as specialized plastics and corrosion-resistant alloys, are being employed to extend the lifespan of valves in harsh environments. Additionally, modern manufacturing techniques, including precision casting and 3D printing, enable the production of high-quality components that meet stringent industry standards.

wafer butterfly valve manufacturers

The role of wafer butterfly valve manufacturers is not limited to production alone. Many companies provide a comprehensive range of services, including design consultation and on-site support. This collaboration with customers ensures that the valves are tailored to meet specific operational needs, enhancing overall system performance. Moreover, manufacturers often offer training programs to educate operators on best practices for installation and maintenance, further maximizing the efficiency of these critical components.

Another notable trend in the sector is the shift toward automation and smart technologies. With the rise of Industry 4.0, many wafer butterfly valve manufacturers are integrating smart features into their products. These advancements allow for remote operation and monitoring, providing operators with real-time data on valve performance and flow rates. Such innovations not only improve operational efficiency but also contribute to proactive maintenance, reducing downtime and associated costs.

In conclusion, wafer butterfly valve manufacturers are essential players in the industrial landscape, providing innovative solutions that enhance efficiency and sustainability. Their commitment to quality, customer service, and technological advancement ensures that industries can rely on these valves for optimal performance in their operations. As we move towards a more automated and eco-friendly future, the role of these manufacturers will only become more critical in meeting the demands of a rapidly changing industrial environment.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024