2 月 . 04, 2025 02:05 Back to list

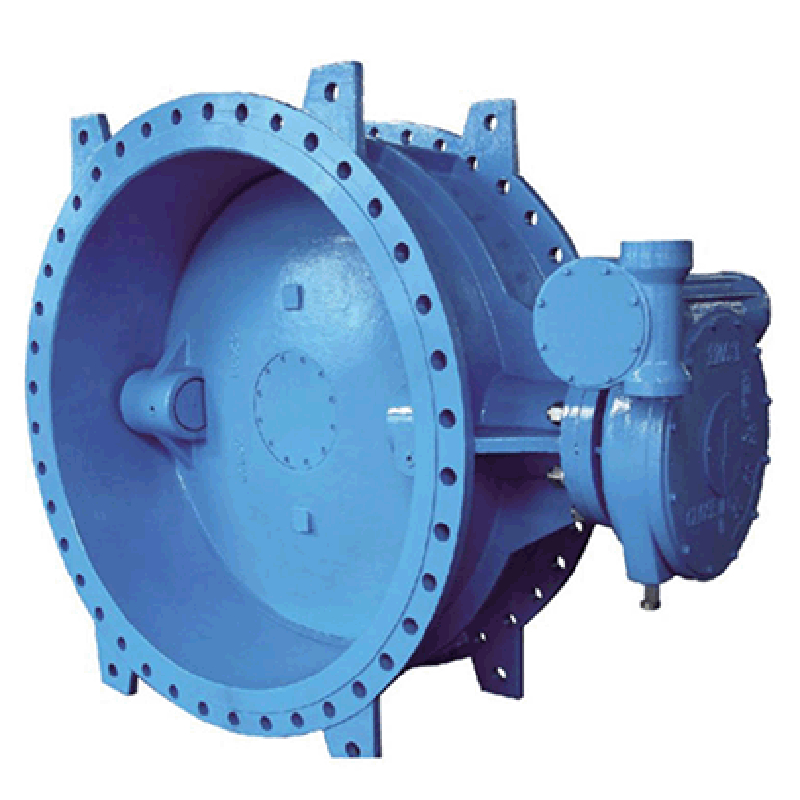

vulcanized seat flange butterfly valve

Selecting the right valve for fluid control systems is a critical decision that affects both operational efficiency and maintenance costs. The vulcanized seat flange butterfly valve is gaining popularity in various industries due to its unique features and benefits. By understanding this type of valve, businesses can optimize their processes more effectively.

In terms of authority and trustworthiness, manufacturers of vulcanized seat flange butterfly valves employ rigorous testing standards, ensuring each product meets international quality benchmarks. Certifications from relevant industry bodies serve as a testament to their reliability and quality, providing customers with assurance of their investment. Professionals educated in valve technology will appreciate the versatility that vulcanized seat flange butterfly valves offer. Unlike some systems that require multiple different types of valves, these can often serve numerous roles within industrial applications, reducing inventory needs and simplifying operations management. Their ability to maintain a tight seal even in low-pressure scenarios is particularly useful for sensitive applications such as food and beverage production, where contamination control is critical. Documentation and support from trusted manufacturers further enhance the expertise associated with using vulcanized seat flange butterfly valves. Detailed manuals and readily available customer support ensure that operators can maximize the valve's benefits while troubleshooting potential issues effectively. Furthermore, the environmental benefits cannot be overlooked. The durability and efficiency of vulcanized seat flange butterfly valves reduce waste associated with frequent replacements and energy losses from inefficient flow control. Companies focused on sustainability will find these valves align well with eco-friendly initiatives. In conclusion, the vulcanized seat flange butterfly valve is a highly advantageous component for industries requiring reliable and efficient fluid control. Its unique construction enhances durability, reduces maintenance, and fits a wide range of applications. As an exemplary choice for both performance and cost-effectiveness, incorporating this valve into your operational strategy can significantly benefit both the bottom line and operational efficiency.

In terms of authority and trustworthiness, manufacturers of vulcanized seat flange butterfly valves employ rigorous testing standards, ensuring each product meets international quality benchmarks. Certifications from relevant industry bodies serve as a testament to their reliability and quality, providing customers with assurance of their investment. Professionals educated in valve technology will appreciate the versatility that vulcanized seat flange butterfly valves offer. Unlike some systems that require multiple different types of valves, these can often serve numerous roles within industrial applications, reducing inventory needs and simplifying operations management. Their ability to maintain a tight seal even in low-pressure scenarios is particularly useful for sensitive applications such as food and beverage production, where contamination control is critical. Documentation and support from trusted manufacturers further enhance the expertise associated with using vulcanized seat flange butterfly valves. Detailed manuals and readily available customer support ensure that operators can maximize the valve's benefits while troubleshooting potential issues effectively. Furthermore, the environmental benefits cannot be overlooked. The durability and efficiency of vulcanized seat flange butterfly valves reduce waste associated with frequent replacements and energy losses from inefficient flow control. Companies focused on sustainability will find these valves align well with eco-friendly initiatives. In conclusion, the vulcanized seat flange butterfly valve is a highly advantageous component for industries requiring reliable and efficient fluid control. Its unique construction enhances durability, reduces maintenance, and fits a wide range of applications. As an exemplary choice for both performance and cost-effectiveness, incorporating this valve into your operational strategy can significantly benefit both the bottom line and operational efficiency.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024