10 月 . 20, 2024 08:50 Back to list

vulcanized seat flange butterfly valve

Understanding the Vulcanized Seat Flange Butterfly Valve

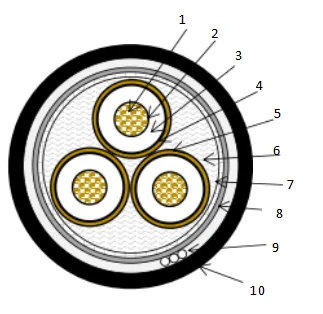

The vulcanized seat flange butterfly valve represents an innovative advancement in fluid control technology, designed to provide efficient and reliable sealing in various industrial applications. This valve type combines the robust features of butterfly valves with the advantages of a vulcanized rubber seat, making it a popular choice across multiple sectors such as water treatment, chemical processing, and HVAC systems.

What is a Butterfly Valve?

A butterfly valve is a type of flow control device that consists of a rotating disc or 'butterfly,' which pivots around a central axis within a pipe. When the disc is rotated, it either allows or restricts the flow of fluid through the pipeline. Butterfly valves are favored for their lightweight design, quick operation, and simple construction, making them an efficient option for regulating flow in large systems.

The Role of the Vulcanized Seat

The seat of a butterfly valve is critical because it enhances the sealing capability of the valve. In the case of a vulcanized seat, rubber is treated with heat and chemicals to enhance its durability and resilience. This process, known as vulcanization, results in a material that can withstand extreme temperatures, resist chemical corrosion, and provide excellent flexibility.

By integrating a vulcanized rubber seat within the flange butterfly valve design, manufacturers can significantly improve the valve's sealing performance. This is particularly important in applications where complete closure is necessary to prevent leaks or unintended flow, thus ensuring the safety and efficiency of the system.

Advantages of Vulcanized Seat Flange Butterfly Valves

vulcanized seat flange butterfly valve

2. Temperature and Chemical Resistance Thanks to the vulcanization process, the rubber seat can endure a wide range of temperatures and resist various chemicals, making it suitable for diverse applications.

3. Reduced Maintenance With a robust vulcanized seat, these valves experience less wear over time compared to conventional rubber options. This durability translates to lower maintenance needs and longer operational life.

4. Ease of Installation The flange connection format allows for straightforward installation and removal of the valve within piping systems, facilitating maintenance and repairs without extensive system downtime.

5. Cost-effective Solution While the initial investment might be slightly higher than standard valves, the longevity and reduced maintenance costs associated with vulcanized seat flange butterfly valves make them a cost-effective choice in the long run.

Applications

Vulcanized seat flange butterfly valves find applications in various industries. In water treatment facilities, they efficiently regulate flow, providing essential control over the treatment processes. In the chemical industry, their resistance to aggressive substances makes them ideal for managing corrosive fluids. Additionally, HVAC systems benefit from these valves as they help optimize airflow while maintaining energy efficiency.

Conclusion

In summary, the vulcanized seat flange butterfly valve stands out as an essential component in modern fluid control systems. Its unique design leverages the strengths of both butterfly valves and vulcanized rubber, delivering exceptional sealing performance and durability. As industries continue to evolve, the demand for reliable and efficient flow control solutions will only grow, making the vulcanized seat flange butterfly valve an indispensable asset for engineers and operators alike. By investing in this technology, industries can enhance their operational efficiency, safety, and overall performance.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024