10 月 . 12, 2024 21:11 Back to list

u type butterfly valve

Understanding the U-Type Butterfly Valve Design, Applications, and Advantages

The U-type butterfly valve has gained significant traction in industrial applications due to its unique design and functionality. This article delves into the specifics of the U-type butterfly valve, exploring its structure, benefits, applications, and some considerations for its use.

What is a U-Type Butterfly Valve?

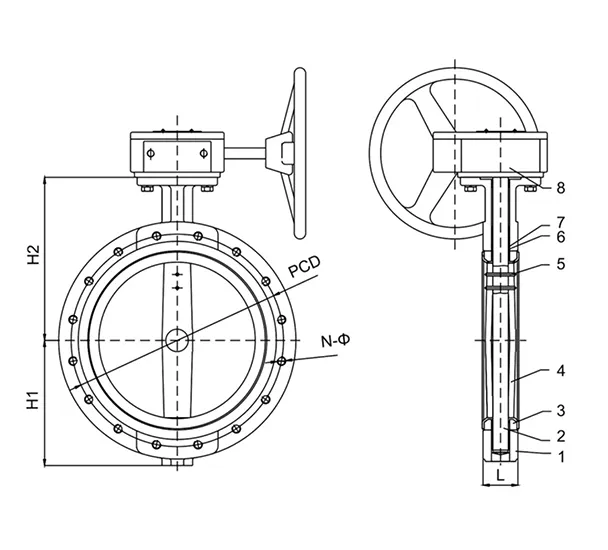

A butterfly valve is a type of flow control device that consists of a rotating disc, or butterfly, which is mounted on a shaft. The U-type butterfly valve features a U-shaped body design that provides several advantages over traditional butterfly valves. This innovative design not only enhances its operational efficiency but also ensures better sealing and flow characteristics.

Design Features

The U-shaped design of the valve body facilitates smoother fluid flow, reducing turbulence and energy loss. The valve consists of several components, including

1. Disc The disc controls the flow of fluid through the valve. When the valve is in the closed position, the disc is perpendicular to the flow, creating a seal. When opened, the disc rotates to allow fluid to pass through.

2. Shaft The shaft connects to the disc and rotates to control the valve's position. The placement of the shaft within the U-shaped body helps in achieving efficient torque transmission.

3. Seals U-type butterfly valves often incorporate advanced sealing materials that provide a reliable seal even under high-pressure conditions. This is crucial in preventing leaks and ensuring system integrity.

4. Actuation Mechanism The valve can be operated manually or automatically, with options for electric, pneumatic, or hydraulic actuators, making it versatile for various operational needs.

Advantages of U-Type Butterfly Valves

1. Enhanced Flow Control The U-shaped body minimizes flow resistance, allowing for improved flow control. This is particularly beneficial in systems where maintaining flow efficiency is critical.

u type butterfly valve

3. Lightweight Construction The design typically results in a lighter valve, reducing the overall load on piping systems and supporting structures.

4. Cost-Effective Their efficient design can lead to reduced operational costs due to lower energy consumption and minimal maintenance requirements.

5. Wide Range of Operating Conditions U-type butterfly valves can be designed to handle various temperatures and pressures, making them suitable for a multitude of industry applications.

Applications

Due to their unique advantages, U-type butterfly valves find applications across various sectors, including

- Water Treatment They are commonly used in water supply systems for their effective flow regulation and reliable sealing capabilities. - Oil and Gas In the oil and gas industry, U-type butterfly valves are utilized in pipelines and distribution networks where robust performance is required under varying pressure conditions.

- Chemical Processing Their resistance to corrosion and ability to handle aggressive fluids make them ideal for chemical processing plants.

- HVAC Systems These valves are employed in heating, ventilation, and air conditioning systems for temperature and air flow control.

Conclusion

The U-type butterfly valve is a remarkable innovation that combines functionality with efficiency, making it a preferred choice in numerous industrial applications. Its unique design allows for enhanced flow control, cost savings, and versatility in operation. As industries continue to evolve and seek improved solutions for fluid regulation, the U-type butterfly valve is poised to play a critical role in future developments, offering reliability and performance in diverse environments.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024