10 月 . 18, 2024 18:15 Back to list

u type butterfly valve

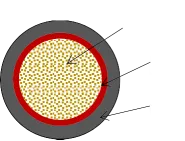

Understanding U-Type Butterfly Valves Benefits and Applications

U-Type butterfly valves are a critical component in various industrial applications, primarily used for controlling fluid flow in large pipes. Their unique design combines efficiency, reliability, and ease of operation, making them a favored choice among engineers and contractors.

Design Features

The U-Type butterfly valve features a disc that rotates around an axis perpendicular to the flow direction, allowing for smooth and rapid operation. Its ‘U’ shaped body provides enhanced structural integrity while minimizing resistance to flow. This configuration not only reduces energy consumption but also extends the lifecycle of the valve itself.

One of the key advantages of U-Type butterfly valves is their compact design. They occupy less space compared to traditional gate or globe valves, making them ideal for applications where installation space is at a premium. The robust construction ensures that they can withstand high pressures and temperatures, further broadening their usability across different sectors.

Benefits of U-Type Butterfly Valves

1. Efficiency U-Type butterfly valves facilitate quick adjustments to flow rates, which is particularly advantageous in systems requiring frequent regulation. This can enhance overall system efficiency and reduce energy costs.

u type butterfly valve

2. Cost-Effective Due to their simple design and ease of maintenance, U-Type butterfly valves are often more cost-effective compared to other valve types. Their longevity also contributes to savings on replacements and repairs.

3. Versatility These valves are suitable for various fluids, including liquids, gases, and slurries, which makes them versatile for industries such as water treatment, chemical processing, and HVAC systems.

4. Low Torque Requirements The design allows for low torque operation, which means they can be easily operated without the need for extensive actuation systems. This makes them a favorable choice for manual, electric, or pneumatic operations.

Applications

U-Type butterfly valves are widely used across various sectors. In the water and wastewater management industry, they regulate flow in treatment plants and distribution systems. In chemical processing, their ability to handle corrosive materials makes them indispensable. They are also crucial in industrial applications like power generation, where they control steam and other fluids with precision.

In conclusion, U-Type butterfly valves are a vital part of modern fluid control systems. Their unique design and numerous benefits make them essential for a variety of applications. As industries continue to evolve and demand greater energy efficiency and reliability, the popularity of U-Type butterfly valves is expected to rise, solidifying their place in the engineering toolkit. Whether for new installations or upgrading existing systems, investing in U-Type butterfly valves can lead to significant operational improvements.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024