2 月 . 19, 2025 10:23 Back to list

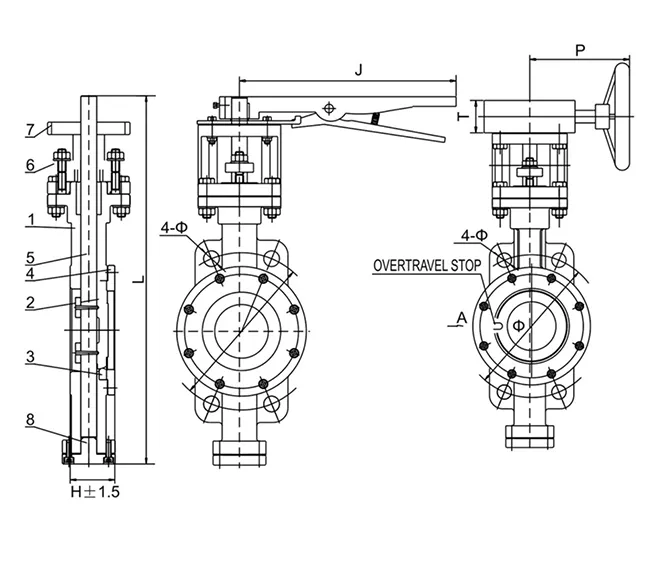

Double Eccentric Flange Butterfly Valve

In the realm of industrial engineering, where precision and reliability are paramount, trunnion mounted components have garnered significant attention. Designed to facilitate enhanced support and stability, they play an indispensable role across numerous applications including, but not limited to, heavy machinery, petrochemical plants, and complex manufacturing systems. Experienced engineers recognize the unique advantages offered by trunnion mounted setups specifically in ball valve systems—a testament to the sophistication and necessity of such mechanisms.

Operators with firsthand experience appreciate the ease of operation provided by trunnion mounted configurations. Unlike their floating ball counterparts, these valves necessitate minimal torque to function, markedly enhancing the ease with which systems are engaged or disengaged. This efficiency not only minimizes energy consumption but also enhances operational readiness in time-sensitive situations. Trustworthiness is further amplified by the reassurance that comes with knowing the built-in support mechanisms are engineered to protect against catastrophic failure. From a product perspective, the trunnion mounting architecture is a culminatory point in evolutionary design processes calibrated for the most critical environment. Its engineering is bolstered by years of iterative feedback and technological advancements. This pedigree is evident in the proliferation of diverse configurations, materials, and specifications available in the market today. Such diversity empowers customization, allowing products to meet exacting client specifications across various sectors. Looking towards the future, the trajectory of trunnion mounted technologies seems set to rise, with innovations continuously emerging to enhance product performance and environmental compliance. As regulatory landscapes evolve and the demand for heightened safety mechanisms grows, trunnion mounted systems are poised to adapt and meet these challenges, solidifying their status as indispensable components within their respective fields. Trunnion mounted systems, especially within ball valve applications, remain an exemplar of industrial ingenuity. They embody the principles of expert craftsmanship, authoritative reliability, and trustworthy performance—traits that not only ensure ongoing relevance but also highlight the superior engineering synonymous with these crucial industrial elements.

Operators with firsthand experience appreciate the ease of operation provided by trunnion mounted configurations. Unlike their floating ball counterparts, these valves necessitate minimal torque to function, markedly enhancing the ease with which systems are engaged or disengaged. This efficiency not only minimizes energy consumption but also enhances operational readiness in time-sensitive situations. Trustworthiness is further amplified by the reassurance that comes with knowing the built-in support mechanisms are engineered to protect against catastrophic failure. From a product perspective, the trunnion mounting architecture is a culminatory point in evolutionary design processes calibrated for the most critical environment. Its engineering is bolstered by years of iterative feedback and technological advancements. This pedigree is evident in the proliferation of diverse configurations, materials, and specifications available in the market today. Such diversity empowers customization, allowing products to meet exacting client specifications across various sectors. Looking towards the future, the trajectory of trunnion mounted technologies seems set to rise, with innovations continuously emerging to enhance product performance and environmental compliance. As regulatory landscapes evolve and the demand for heightened safety mechanisms grows, trunnion mounted systems are poised to adapt and meet these challenges, solidifying their status as indispensable components within their respective fields. Trunnion mounted systems, especially within ball valve applications, remain an exemplar of industrial ingenuity. They embody the principles of expert craftsmanship, authoritative reliability, and trustworthy performance—traits that not only ensure ongoing relevance but also highlight the superior engineering synonymous with these crucial industrial elements.

Share

Prev:

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024