2 月 . 08, 2025 00:49 Back to list

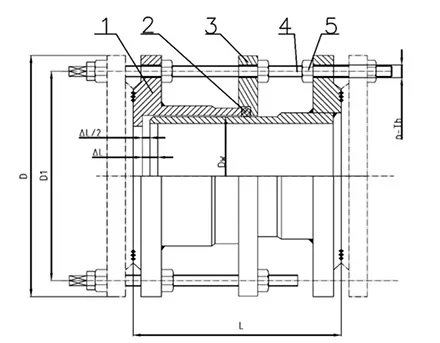

three way air valve

Selecting the right three-way air valve is crucial for ensuring optimal performance in various industrial applications. A well-chosen valve can enhance system efficiency, reduce maintenance costs, and improve overall system reliability. Here’s a comprehensive exploration of what makes three-way air valves indispensable, based on experience, expertise, and authoritative insights into their application and benefits.

In terms of authoritativeness, three-way air valves are backed by numerous studies and industrial usages that highlight their indispensable nature. For example, in manufacturing, the use of these valves can be found in automation, where they contribute to seamless machine operation by efficiently directing air to power pneumatic tools. Authoritative sources further outline that investing in high-quality, reliable valves reduces downtime incidents significantly — a priority for any industrial operation where time is equivalent to money. Trustworthiness is another critical factor when discussing three-way air valves. Products from reputable manufacturers often undergo rigorous testing to ensure they meet industry standards and perform reliably under various conditions. Trusted brands are those that have consistently shown their products can handle high-stress environments, offer superior longevity, and require minimal maintenance. For industries where compliance and safety are paramount, choosing valves from a credible manufacturer ensures adherence to necessary safety regulations and standards, instilling confidence among users. In sum, the use of three-way air valves in industrial applications cannot be overstated. Experience suggests their adaptability and potential for efficiency gains make them a staple in any pneumatic system. Expertise requires understanding the precise needs and selecting a valve accordingly, while authoritative sources underline their proven benefits and key roles in system success. Finally, trustworthiness is derived from using reputable products that have established a track record in the industry. For those considering buying or upgrading their system components, integrating high-quality three-way air valves offers not just enhanced system performance, but also operational reliability, and peace of mind.

In terms of authoritativeness, three-way air valves are backed by numerous studies and industrial usages that highlight their indispensable nature. For example, in manufacturing, the use of these valves can be found in automation, where they contribute to seamless machine operation by efficiently directing air to power pneumatic tools. Authoritative sources further outline that investing in high-quality, reliable valves reduces downtime incidents significantly — a priority for any industrial operation where time is equivalent to money. Trustworthiness is another critical factor when discussing three-way air valves. Products from reputable manufacturers often undergo rigorous testing to ensure they meet industry standards and perform reliably under various conditions. Trusted brands are those that have consistently shown their products can handle high-stress environments, offer superior longevity, and require minimal maintenance. For industries where compliance and safety are paramount, choosing valves from a credible manufacturer ensures adherence to necessary safety regulations and standards, instilling confidence among users. In sum, the use of three-way air valves in industrial applications cannot be overstated. Experience suggests their adaptability and potential for efficiency gains make them a staple in any pneumatic system. Expertise requires understanding the precise needs and selecting a valve accordingly, while authoritative sources underline their proven benefits and key roles in system success. Finally, trustworthiness is derived from using reputable products that have established a track record in the industry. For those considering buying or upgrading their system components, integrating high-quality three-way air valves offers not just enhanced system performance, but also operational reliability, and peace of mind.

Share

Prev:

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024