12 月 . 03, 2024 18:53 Back to list

threaded ball valve

Threaded Ball Valve An Essential Component in Fluid Control Systems

In the realm of fluid control systems, the threaded ball valve plays a pivotal role in managing the flow of liquids and gases. This type of valve harnesses the spherical disc mechanism to regulate passage, ensuring that systems operate efficiently and effectively. This article explores the structure, functionality, applications, and advantages of threaded ball valves, highlighting their importance in various industries.

Understanding Threaded Ball Valves

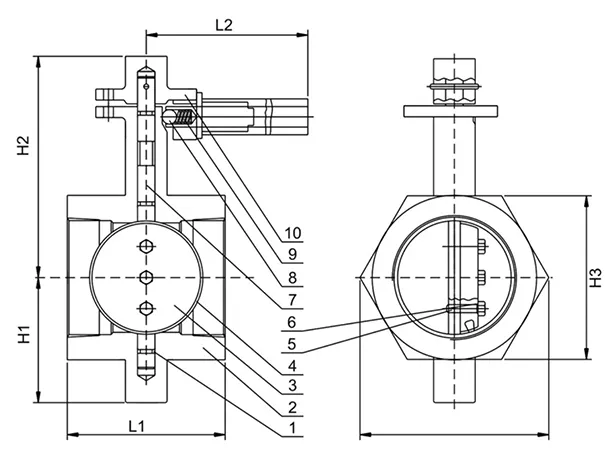

A threaded ball valve is characterized by its unique design, which consists of a ball with a hole (or port) through its center, allowing it to control the flow of fluids. The ball rotates within its chamber, and when the hole aligns with the flow path, the valve opens, allowing fluid to pass through. Conversely, when the ball is rotated 90 degrees, the fluid flow is obstructed, effectively closing the valve.

The threaded aspect refers to the types of connections used to install the valve into a piping system. Threaded connections provide a secure fit and allow for easy assembly and disassembly, making maintenance more manageable. These valves typically come in various materials, such as brass, stainless steel, and plastic, each chosen based on the nature of the fluid being controlled and the specific requirements of the application.

Functionality and Operation

Threaded ball valves are known for their straightforward operation and reliability. The key advantage lies in their ability to provide a tight seal, which prevents leaks and minimizes the risk of contamination. The design allows the valve to be fully open, fully closed, or anywhere in between, making it suitable for throttling applications, although they are primarily designed for on/off control.

The mechanism involves a simple handle or lever that, when turned, rotates the ball inside the valve. This intuitive operation means that even personnel without extensive training can effectively manage the valve, making it a favorite in many industrial settings.

Applications Across Industries

The versatility of threaded ball valves renders them suitable for an array of applications. They can be found in industries such as

2. Chemical Processing Their resistance to corrosive substances makes them ideal for chemical manufacturing environments, where precise control over aggressive fluids is crucial.

threaded ball valve

3. Water Treatment Threaded ball valves regulate water distribution and treatment processes, ensuring that systems maintain optimal performance and compliance with safety standards.

4. Pharmaceuticals In the pharmaceutical industry, where maintaining sterile conditions is paramount, these valves assist in controlling flow without contamination.

5. HVAC Systems Threaded ball valves are often employed in heating, ventilation, and air conditioning systems to regulate and control airflow and temperature.

Advantages of Threaded Ball Valves

Threaded ball valves present several notable advantages

- Durability Constructed from robust materials, these valves can withstand high pressures and temperatures, ensuring longevity even in demanding environments.

- Low Torque Requirements The design allows for easy actuation, requiring minimal force to open or close, which reduces wear and tear on the valve and associated equipment.

- Compact Design Their relatively small size compared to other valve types makes them easier to install in tight spaces without sacrificing performance.

- Cost-Effective Maintenance With simple design features, threaded ball valves can be easily maintained or replaced, lowering operational costs and downtime.

Conclusion

In summary, threaded ball valves are a fundamental element in fluid control systems, offering reliability, durability, and versatility across various industries. Their straightforward operation and excellent sealing capabilities make them indispensable in ensuring safe and efficient fluid management. As technology advances, we can expect continued innovation in valve design and materials, further enhancing the performance and application of threaded ball valves in the future. In an age where precision and safety are paramount, these valves prove to be vital components in the machinery of countless industrial processes.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024