10 月 . 21, 2024 21:01 Back to list

Teflon Coated Butterfly Valve for Enhanced Performance and Durability in Fluid Control Applications

The Role of Teflon Butterfly Valves in Industrial Applications

Teflon butterfly valves have become increasingly popular in various industrial applications due to their unique properties and abilities. This type of valve employs a simple yet effective mechanism to control fluid flow, making it an essential component in many systems, from chemical processing to food production. Understanding the features and advantages of Teflon butterfly valves is crucial for industries seeking reliability and efficiency in their operations.

What is a Butterfly Valve?

A butterfly valve consists of a disc that rotates around a shaft, controlling the flow of fluid through a pipe. The disc's position can be adjusted to fully open, partially open, or fully close the flow. This design allows for quick and easy operation, which is one of the many reasons butterfly valves are favored in various applications.

The Importance of Teflon in Butterfly Valves

Teflon, also known as Polytetrafluoroethylene (PTFE), is a synthetic fluoropolymer renowned for its non-stick properties, high chemical resistance, and ability to withstand a wide range of temperatures. These properties make Teflon an ideal material for use in butterfly valves, particularly in industries such as pharmaceuticals, petrochemicals, and food processing.

The use of Teflon in butterfly valves provides several significant advantages

1. Chemical Resistance Teflon is inert to most chemicals, which allows butterfly valves equipped with Teflon seals or linings to handle corrosive and aggressive substances without degrading or leaking. This is critical in industries like chemical manufacturing, where exposure to harsh substances is common.

2. Temperature Tolerance Teflon can function effectively across a wide temperature range, typically from -450°F to 500°F (-268°C to 260°C). This resilience ensures that Teflon butterfly valves remain operational in extreme conditions, a common requirement in many industrial processes.

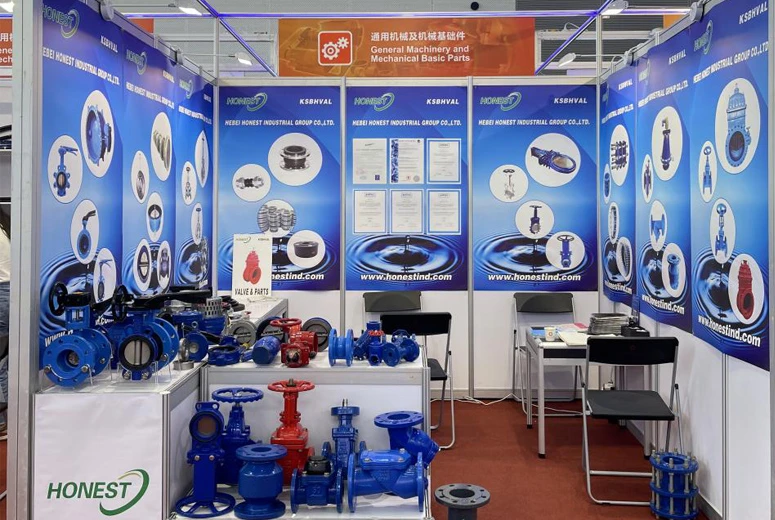

teflon butterfly valve

3. Low Friction Coefficient Teflon's non-stick properties reduce friction between the valve components. As a result, Teflon butterfly valves exhibit smooth operation, requiring less torque to open and close. This efficiency not only minimizes wear and tear on the valve but also leads to lower energy consumption over time.

4. Ease of Maintenance The smooth surface of Teflon makes it less susceptible to build-up and contaminants, which facilitates easier cleaning and maintenance. This is particularly important in industries with stringent hygiene requirements, such as food production.

Applications of Teflon Butterfly Valves

The versatility of Teflon butterfly valves allows them to be used in a wide range of applications

- Pharmaceutical Industry In pharmaceutical manufacturing, the need for sterile and contamination-free environments is paramount. Teflon butterfly valves play a crucial role in controlling the flow of raw materials and finished products without risk of contamination.

- Food Processing Similar to pharmaceuticals, the food industry demands high hygiene standards. Teflon butterfly valves help maintain the integrity of food products, ensuring that they are safe for consumption and free from contaminants.

- Chemical Processing In chemical plants, processes often involve harsh chemicals. Teflon butterfly valves allow for efficient flow control while providing resistance against corrosive substances, ensuring a longer lifespan for the equipment.

Conclusion

Teflon butterfly valves provide a robust solution for fluid control in diverse industrial settings. Their unique properties, such as chemical resistance, temperature tolerance, and ease of maintenance, make them an invaluable asset for industries that prioritize safety, efficiency, and reliability. As technology continues to evolve, the demand for advanced valve systems like Teflon butterfly valves will only increase, highlighting their significance in modern industrial applications.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024