10 月 . 21, 2024 14:01 Back to list

Teflon Coated Butterfly Valve for Enhanced Performance and Durability

The Advantages and Applications of Teflon Butterfly Valves

Butterfly valves are vital components in various industrial applications, primarily used to regulate the flow of liquids and gases. Among the myriad types available, Teflon butterfly valves stand out due to their unique properties and advantages. This article explores the attributes of Teflon butterfly valves, their applications, and why they are a preferred choice in many industries.

Understanding Teflon Butterfly Valves

Teflon, or Polytetrafluoroethylene (PTFE), is a high-performance plastic known for its excellent chemical resistance, low friction properties, and ability to withstand extreme temperatures. When used in butterfly valves, Teflon provides an exceptional sealing surface that is both durable and resistant to harsh environments.

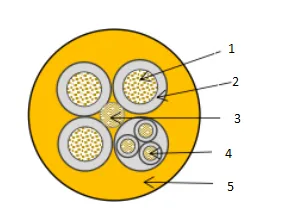

A butterfly valve consists of a disc that rotates to open or close the flow path, allowing for quick regulation of flow. In Teflon butterfly valves, the disc and body may be coated with Teflon or made entirely from it, ensuring a smooth operation and minimizing wear and tear.

Key Advantages of Teflon Butterfly Valves

1. Chemical Resistance One of the primary advantages of Teflon butterfly valves is their remarkable resistance to a broad range of chemicals, including acids, bases, solvents, and corrosive substances. This makes them ideal for use in chemical processing, wastewater treatment, and food processing industries where exposure to aggressive chemicals is common.

2. High-Temperature Tolerance Teflon can operate effectively in a wide temperature range, typically from -50°F to +500°F (-45°C to +260°C). This property allows Teflon butterfly valves to be used in applications that require high-temperature resistance, such as steam lines and hot water systems.

3. Low Friction and Wear Teflon's low friction characteristics reduce the wear between the valve components, resulting in a longer lifespan and reduced maintenance needs. This feature is particularly beneficial in processes where frequent valve operation is required.

4. Lightweight and Compact Design Teflon butterfly valves are generally lighter and more compact compared to metal valves, which makes them easier to install and handle. Their design also allows for space savings in piping layouts, which is a crucial factor in many industrial settings.

teflon butterfly valve

5. Excellent Seal Quality The Teflon coating provides a superior sealing surface, minimizing the risk of leakage. This is essential for maintaining safety and efficiency in systems that transport hazardous materials.

Applications of Teflon Butterfly Valves

Teflon butterfly valves find applications across a wide range of sectors

- Chemical Processing In facilities where corrosive chemicals are handled, Teflon butterfly valves are utilized to ensure safe and efficient flow control.

- Food and Beverage The food industry demands strict hygiene standards, and Teflon's non-stick properties and resistance to bacterial growth make these valves suitable for food processing and packaging.

- Pharmaceuticals In the pharmaceutical industry, Teflon valves are used for their cleanability and ability to handle various active ingredients without contamination.

- Water Treatment Teflon butterfly valves are employed in sewage and wastewater treatment plants to manage flow and ensure effective treatment processes.

- HVAC Systems They are also used in Heating, Ventilation, and Air Conditioning systems to control the flow of air and fluids efficiently.

Conclusion

Teflon butterfly valves are an invaluable asset in various industries due to their chemical resistance, high-temperature tolerance, low friction properties, lightweight design, and excellent sealing capabilities. Their ability to withstand harsh conditions while providing reliable performance makes them a preferred choice for many applications. As industries continue to evolve and face more challenges related to fluid management, the demand for Teflon butterfly valves is likely to grow, reinforcing their role as a critical component in modern engineering solutions. Investing in high-quality Teflon butterfly valves can lead to increased efficiency, reduced maintenance costs, and, most importantly, enhanced safety across operations.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024