9 月 . 22, 2024 18:05 Back to list

swing type check valve

Understanding Swing Type Check Valves An Overview

Swing type check valves are essential components in various piping systems, primarily utilized to prevent backflow and ensure the unidirectional flow of liquids or gases. Their design and operation play a critical role in maintaining the efficiency and safety of a system. In this article, we will delve into the characteristics, advantages, and applications of swing type check valves.

Design and Functionality

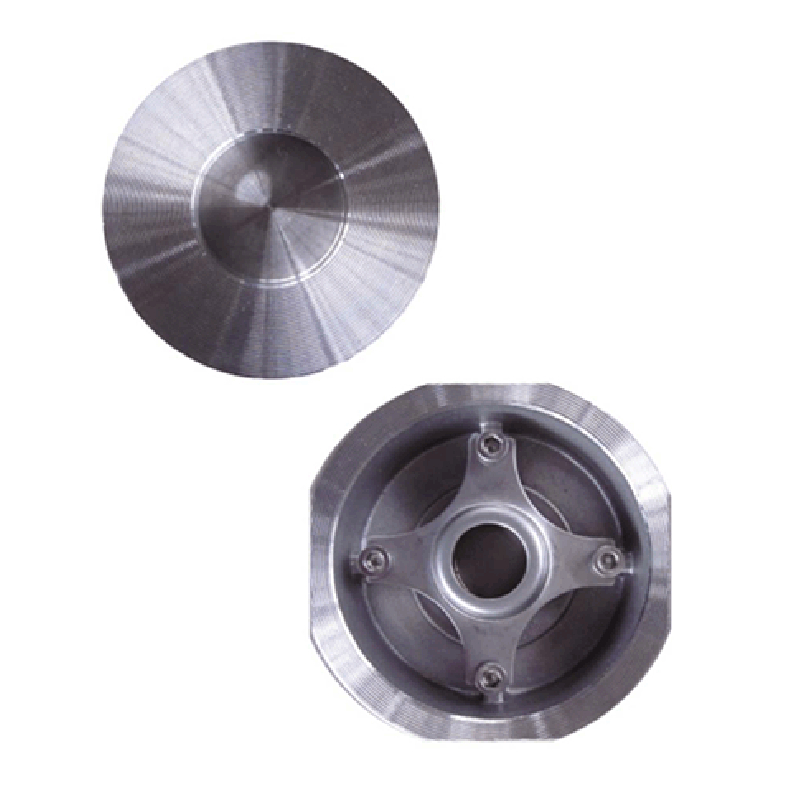

A swing type check valve operates based on a simple yet effective mechanical system. It features a disc or a swinging arm that pivots around a hinge. When fluid flows in the intended direction, the force of the fluid opens the valve, allowing smooth passage. However, if the flow attempts to reverse, the disc swings against the seat, effectively closing the valve and preventing backflow. This mechanism is vital in applications where reverse flow can lead to operational hazards or contamination.

Constructed from various materials, including bronze, stainless steel, and PVC, swing check valves are designed to withstand different pressures and temperatures. Their robust design makes them suitable for a diverse range of applications, including water supply systems, sewage treatment plants, and industrial processes.

Advantages of Swing Type Check Valves

One of the primary advantages of swing type check valves is their simplicity. Their straightforward design means fewer moving parts compared to other types of check valves, leading to lower maintenance needs and higher reliability. The absence of a spring mechanism reduces the potential points of failure, making swing check valves less prone to malfunction.

swing type check valve

Another significant benefit is their low-pressure drop. Because the disc swings open fully, swing type check valves provide minimal resistance to the fluid flow, which optimizes system efficiency. This characteristic is particularly advantageous in high-flow applications, where maintaining pressure and flow rate is crucial.

Moreover, their installation flexibility makes them ideal for various orientations. Swing check valves can be installed vertically or horizontally, accommodating different piping layouts without compromising their functionality. However, it is essential to ensure the valve is installed in the correct orientation to operate effectively.

Applications

Swing type check valves are widely used across multiple industries. In water supply systems, they prevent backflow that could contaminate drinking water. In the oil and gas sector, they protect pipelines from reverse flow, which could lead to dangerous leaks or ruptures. Moreover, they are commonly found in HVAC systems, marine applications, and irrigation systems.

Their versatility also extends to processing and manufacturing sectors, where they help maintain the integrity of fluid transfer systems. Whether it’s in food processing, chemical production, or pharmaceuticals, swing check valves ensure that products remain uncontaminated and that processes run smoothly.

Conclusion

In conclusion, swing type check valves are integral components in many fluid handling systems. Their reliable performance, ease of maintenance, and versatility in application make them a popular choice across various industries. Understanding the operational principles and benefits of swing check valves can help engineers and system designers make informed decisions when selecting components for their specific needs. As industries continue to evolve, the role of swing check valves in enhancing system efficiency and ensuring safety remains paramount.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024