2 月 . 15, 2025 20:08 Back to list

swing type check valve

Swing type check valves play a crucial role in various industrial applications, ensuring a smooth, one-directional flow of fluids. Their unique design combines practicality with efficiency, enhancing the safety and reliability of fluid systems. In an era where industries demand precision and robust mechanisms, understanding the nuances of swing type check valves is essential for anyone involved in fluid dynamics or industrial maintenance.

Authoritativeness Insights from Industry Leaders Leading manufacturers of swing type check valves, such as Emerson and Flowserve, provide in-depth specifications and guidelines to ensure optimal use. Industry leaders emphasize the significance of regular inspections and maintenance to uphold the pressure and performance levels. Conferences and white papers from these companies underline the importance of understanding fluid velocity and pressure ratings when selecting check valves. These resources become invaluable for engineers and procurement specialists aiming to make informed decisions. Trustworthiness Building Confidence through Rigorous Standards Compliance with international standards such as API, ANSI, and ISO reinforces the reliability of swing type check valves. These standards guarantee that valves are tested for leak-proof performance and can withstand specified pressure ranges. Additionally, third-party certifications and field-operation feedback add layers of trustworthiness. Operators benefit from knowing that these components meet the highest safety and quality criteria, reducing the risk of system failures and costly downtimes. Integrating swing type check valves into fluid systems not only enhances performance but also contributes to overall operational safety. As industries continue to evolve, the demand for reliable components like the swing type check valve remains pivotal. By focusing on the experiences, technical insights, authoritative advice, and trustworthy standards, stakeholders can make informed decisions that drive industrial success. In conclusion, swing type check valves epitomize efficiency and safety in fluid control applications. Their continued relevance in modern systems underscores their indispensable role in industry. For professionals tasked with ensuring optimal system performance, a thorough understanding of these valves is not just beneficial but essential.

Authoritativeness Insights from Industry Leaders Leading manufacturers of swing type check valves, such as Emerson and Flowserve, provide in-depth specifications and guidelines to ensure optimal use. Industry leaders emphasize the significance of regular inspections and maintenance to uphold the pressure and performance levels. Conferences and white papers from these companies underline the importance of understanding fluid velocity and pressure ratings when selecting check valves. These resources become invaluable for engineers and procurement specialists aiming to make informed decisions. Trustworthiness Building Confidence through Rigorous Standards Compliance with international standards such as API, ANSI, and ISO reinforces the reliability of swing type check valves. These standards guarantee that valves are tested for leak-proof performance and can withstand specified pressure ranges. Additionally, third-party certifications and field-operation feedback add layers of trustworthiness. Operators benefit from knowing that these components meet the highest safety and quality criteria, reducing the risk of system failures and costly downtimes. Integrating swing type check valves into fluid systems not only enhances performance but also contributes to overall operational safety. As industries continue to evolve, the demand for reliable components like the swing type check valve remains pivotal. By focusing on the experiences, technical insights, authoritative advice, and trustworthy standards, stakeholders can make informed decisions that drive industrial success. In conclusion, swing type check valves epitomize efficiency and safety in fluid control applications. Their continued relevance in modern systems underscores their indispensable role in industry. For professionals tasked with ensuring optimal system performance, a thorough understanding of these valves is not just beneficial but essential.

Share

Next:

Latest news

-

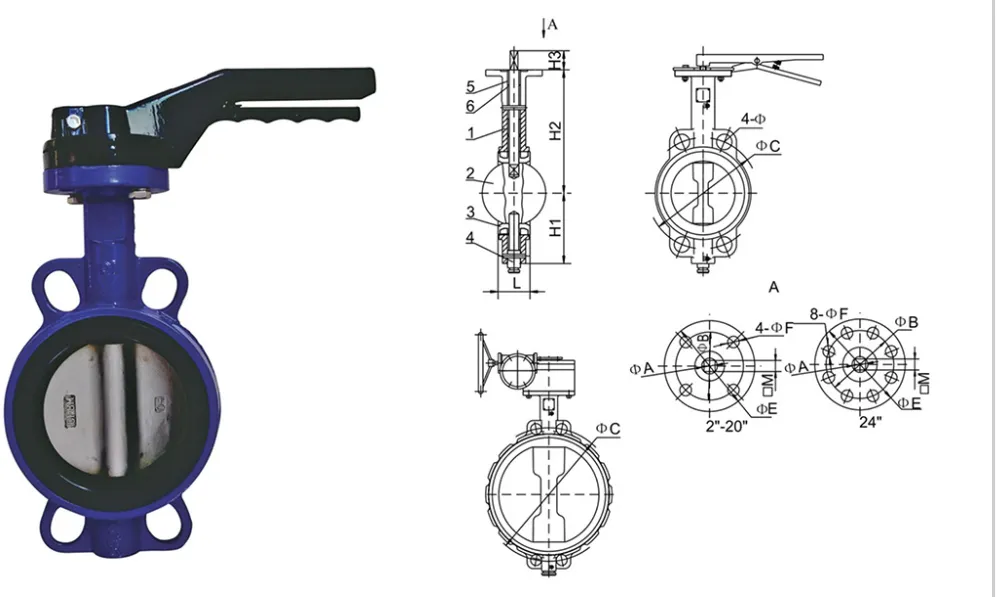

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024