10 月 . 21, 2024 10:17 Back to list

Understanding Swing Type Check Valves and Their Applications in Fluid Systems

Understanding Swing Type Check Valves An Essential Component for Fluid Control

Swing type check valves play a pivotal role in various industrial applications, serving as essential components in fluid control systems. Their primary function is to prevent backflow, ensuring that liquids and gases move in one direction only. As such, they are critical in maintaining the integrity of piping systems and safeguarding equipment from potential damage due to reverse flow.

What is a Swing Type Check Valve?

A swing type check valve is a type of non-return valve that utilizes a disc or flap mechanism to allow flow in one direction while preventing it from flowing in the opposite direction. The valve consists of a valve body, a disc, a seating surface, and a hinge. When fluid flows through the valve in the desired direction, the disc swings open, allowing passage. However, when the fluid attempts to flow back, the disc closes against the seating surface, effectively blocking the reverse flow.

Working Principle

The operation of a swing type check valve is largely influenced by the flow velocity of the fluid. As the fluid pressure rises in the correct direction, it pushes the disc open. The disc is typically weighty enough so that, in the absence of flow, it naturally returns to its closed position. This self-acting nature allows the valve to operate without the need for external power, making it a reliable choice in various settings, from water treatment plants to chemical processing facilities.

Advantages of Swing Type Check Valves

One of the main advantages of swing type check valves is their simple design, which contributes to their reliability and longevity. With fewer moving parts than some other types of check valves, such as lift check valves or globe valves, swing type check valves tend to experience less wear and tear over time. Additionally, they provide minimal resistance to flow, which helps maintain pressure within the system and enhance overall efficiency.

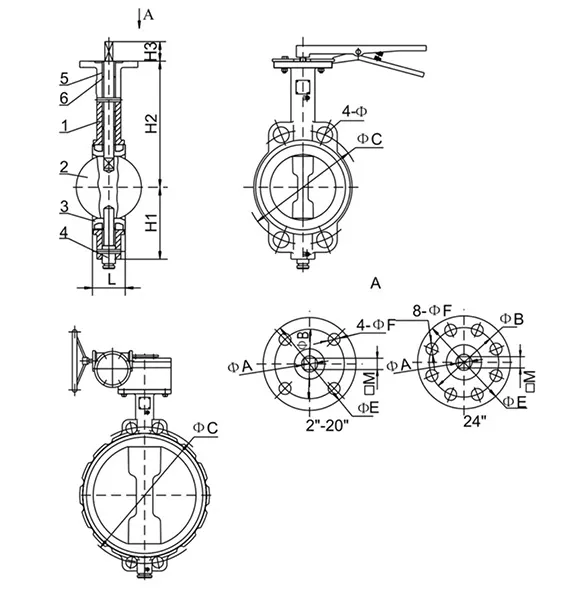

swing type check valve

Moreover, swing check valves can handle a wide range of pressures and temperatures, making them suitable for diverse applications. They can be made from various materials, including stainless steel, cast iron, and plastic, allowing for customization based on the specific requirements of the application.

Common Applications

Swing type check valves are widely used in numerous industries, including HVAC, water and wastewater treatment, oil and gas, and power generation. In HVAC systems, for example, these valves prevent backflow in heating and cooling systems, ensuring optimal performance. In water treatment facilities, they help maintain consistent flow direction, preventing contamination and ensuring the potable quality of water.

In the oil and gas industry, swing check valves are crucial in preventing backflow in pipelines, avoiding potential leaks and spills that could lead to environmental harm. Similarly, power plants use these valves to protect equipment from back pressure that could cause significant damage.

Considerations for Installation

While swing type check valves offer numerous benefits, proper installation is key to their effectiveness. It's essential to install them in a horizontal position for optimal performance, and they should be placed at a distance from pumps to avoid any potential water hammer effects. Additionally, regular inspection and maintenance are important to ensure that the sealing surfaces remain intact and that the disc operates freely.

Conclusion

In conclusion, swing type check valves are integral components in fluid control systems, providing a reliable solution for preventing backflow in a variety of applications. Their simple design, coupled with their efficiency and effectiveness, makes them a preferred choice in many industries. By understanding the function and benefits of swing type check valves, engineers and operators can better design and maintain their fluid systems, ultimately enhancing performance and safety.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024