10 月 . 05, 2024 15:18 Back to list

swing check valve 6 inch

Understanding the 6-Inch Swing Check Valve Design, Function, and Applications

In the realm of industrial fluid management, valves play a crucial role in controlling the flow of liquids and gases. Among the various types of valves, the swing check valve stands out for its unique operational mechanism and effectiveness in preventing backflow. This article delves into the specifics of the 6-inch swing check valve, exploring its design, functionality, and diverse applications.

Design and Construction

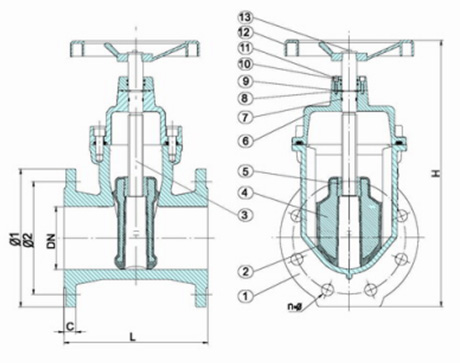

A swing check valve is primarily designed to allow flow in one direction while automatically closing if the flow begins to reverse. The 6-inch variant indicates the diameter of the valve, making it suitable for medium to large-scale pipelines. Typically made from durable materials such as stainless steel, brass, or cast iron, these valves can withstand significant pressure and temperature variations, rendering them suitable for various industrial applications.

The fundamental component of a swing check valve is the disc, which pivots on a hinging mechanism. When fluid flows through the valve, the disc is pushed open by the pressure of the fluid, allowing for unobstructed flow. Conversely, when the flow reverses, gravity and the back pressure of the fluid cause the disc to swing back and seal tightly against the valve seat, thereby preventing backflow.

Functionality

The 6-inch swing check valve operates efficiently in various scenarios. Its simple design ensures minimal resistance to flow, which is a critical factor in maintaining system efficiency. The large diameter allows for significant volumetric flow rates, making it appropriate for use in pipelines that transport water, chemicals, or other fluids across facilities, treatment plants, and manufacturing units.

swing check valve 6 inch

One of the primary advantages of the swing check valve is its ability to handle slurries or fluids laden with solid particles without suffering premature wear. The disc's full closure capability minimizes the risk of fluid seeping back, which can lead to contamination or operational inefficiency. Furthermore, the installation of the valve is straightforward, as it can be oriented horizontally or vertically depending on the system’s configuration.

Applications

The applications for a 6-inch swing check valve are vast and varied. In the water and wastewater sector, these valves are instrumental in preventing backflow in pumps and piping systems, ensuring that clean water is delivered efficiently while avoiding contamination from wastewater sources. In the oil and gas industry, swing check valves are utilized to protect pipelines from potential backflow, thus safeguarding the integrity of the transport system.

In HVAC systems, these valves play a critical role in maintaining pressure and regulating the flow of heating and cooling fluids. Moreover, swing check valves can be found in power plants, chemical processing facilities, and various manufacturing processes where fluid dynamics are critical.

Conclusion

In conclusion, the 6-inch swing check valve offers a reliable and efficient solution for one-way flow control in various industries. Its robust design, coupled with its ability to handle high flow rates and resist backflow, makes it a preferred choice among engineers and facility managers. Understanding the characteristics and benefits of this valve type is essential for selecting the right components for fluid management systems, ensuring operational efficiency while protecting critical infrastructure from fluid dynamics issues. Whether in a municipal water system or an industrial application, the swing check valve continues to play an indispensable role in the smooth functioning of fluid transport mechanisms.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024