11 月 . 01, 2024 03:29 Back to list

6-Inch Swing Check Valve Specifications and Applications for Effective Fluid Control

Understanding the Swing Check Valve A 6-Inch Overview

Swing check valves are essential components in various piping systems, primarily used to prevent backflow in fluid handling applications. When it comes to larger sizes, such as a 6-inch swing check valve, these devices are even more critical in ensuring efficient operation while safeguarding the integrity of the system.

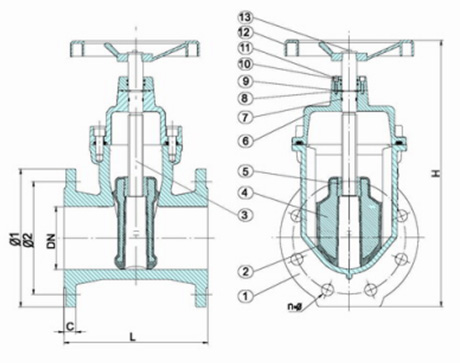

A swing check valve operates on a simple mechanism that allows fluid to flow in one direction while automatically closing to prevent reverse flow. The core component, known as the disc, swings on a hinge as fluid passes through, enabling the valve to open. When fluid flow ceases or reverses, the disc swings back due to gravity or backpressure, effectively sealing the valve and preventing any backflow.

Applications of 6-Inch Swing Check Valves

The 6-inch swing check valve finds applications across various industries, including water treatment, oil and gas, chemical processing, and HVAC systems. In water treatment plants, for example, these valves are crucial in maintaining a unidirectional flow within pipelines, thus protecting pumps and other equipment from potential damage caused by reverse flow.

In oil and gas operations, swing check valves help to manage fluid movement through pipelines, ensuring that the integrity of the system is maintained even during pump shutdowns. Their robust design allows them to handle significant pressure fluctuations, making them ideal for challenging environments.

Benefits of Using Swing Check Valves

swing check valve 6 inch

One of the primary advantages of a swing check valve is its low-pressure drop. Compared to other types of check valves, such as ball or lift check valves, swing check valves create minimal resistance to flow when they are open. This characteristic promotes efficient operation in systems where maintaining pressure is essential.

Moreover, 6-inch swing check valves are typically made from durable materials such as ductile iron or stainless steel, contributing to their longevity. These valves can withstand harsh operating conditions, including extreme temperatures and pressures, ensuring reliability over time.

Installation and Maintenance

Proper installation of a swing check valve is essential for optimal performance. It should be installed in a horizontal position to facilitate the natural gravitational closure of the disc. Regular maintenance is also crucial to ensure the valve continues to function effectively. This includes periodic inspections to check for wear and tear, ensuring that the hinge and disc are free from debris, and lubricating moving parts as necessary.

Conclusion

In summary, a 6-inch swing check valve plays a crucial role in protecting and regulating fluid flow in various industrial applications. Its simple yet effective design, combined with the benefits of low-pressure drop and durability, makes it a preferred choice for engineers and operators alike. Understanding these valves' functionalities and applications can help maximize efficiency and safety in any fluid handling system.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024