2 月 . 15, 2025 21:38 Back to list

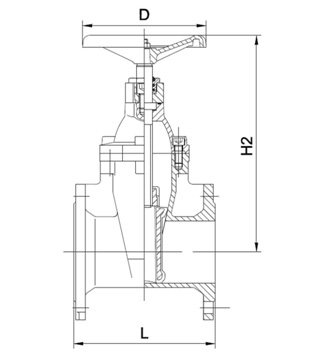

stainless steel globe valve

The stainless steel globe valve stands as a pinnacle of innovation and precision in the realm of fluid control systems. With its origins in the industrial revolution, its adaptation over time showcases a sophisticated synergy of engineering excellence and practical applications. The stainless steel globe valve has continually evolved, reflecting a commitment to quality, longevity, and optimal performance in demanding environments.

Expertise in deploying stainless steel globe valves involves understanding the specific requirements of the application at hand. Factors such as pressure ratings, temperature ranges, and the type of fluid being handled play a crucial role in valve selection. Manufacturers often provide comprehensive guides to assist in choosing the right valve specifications, tailored to distinct industrial needs. Collaborations between engineers and manufacturers foster innovations, leading to the development of more specialized globe valves that cater to niche markets. In terms of authoritativeness, leading manufacturers of stainless steel globe valves have established themselves as industry giants through decades of research and development. These companies invest heavily in fostering technologies that not only enhance valve performance but also comply with global safety standards and regulations. Such compliance assures clients of the reliability and safety of the valves, reducing concerns around operational hazards. Trustworthiness is inherently linked to the valve’s performance history and manufacturer reputation. A manufacturer with a long-standing history of producing high-quality stainless steel globe valves is often a preferred choice. Testimonials from industry professionals further cement confidence, providing anecdotal evidence of the valves’ dependability across various applications. Furthermore, certifications from recognized entities serve as a testament to the valve’s adherence to stringent testing processes and quality checks. While initially an industrial staple, stainless steel globe valves are witnessing a transition into more diverse applications, including residential and commercial plumbing systems. This shift is attributed to their robust nature and the increasing consumer demand for durable and efficient plumbing solutions. The versatile nature of globe valves ensures they remain relevant across different sectors, adapting to new challenges and demonstrating exceptional performance. The stainless steel globe valve is a convergence of past innovations and future possibilities. Representing a blend of experience and expertise, it stands as a trusted component within countless systems worldwide. Its ongoing development and application reinforce its status as an essential asset in fluid management, promising continued relevance and reliability in an ever-evolving industrial landscape.

Expertise in deploying stainless steel globe valves involves understanding the specific requirements of the application at hand. Factors such as pressure ratings, temperature ranges, and the type of fluid being handled play a crucial role in valve selection. Manufacturers often provide comprehensive guides to assist in choosing the right valve specifications, tailored to distinct industrial needs. Collaborations between engineers and manufacturers foster innovations, leading to the development of more specialized globe valves that cater to niche markets. In terms of authoritativeness, leading manufacturers of stainless steel globe valves have established themselves as industry giants through decades of research and development. These companies invest heavily in fostering technologies that not only enhance valve performance but also comply with global safety standards and regulations. Such compliance assures clients of the reliability and safety of the valves, reducing concerns around operational hazards. Trustworthiness is inherently linked to the valve’s performance history and manufacturer reputation. A manufacturer with a long-standing history of producing high-quality stainless steel globe valves is often a preferred choice. Testimonials from industry professionals further cement confidence, providing anecdotal evidence of the valves’ dependability across various applications. Furthermore, certifications from recognized entities serve as a testament to the valve’s adherence to stringent testing processes and quality checks. While initially an industrial staple, stainless steel globe valves are witnessing a transition into more diverse applications, including residential and commercial plumbing systems. This shift is attributed to their robust nature and the increasing consumer demand for durable and efficient plumbing solutions. The versatile nature of globe valves ensures they remain relevant across different sectors, adapting to new challenges and demonstrating exceptional performance. The stainless steel globe valve is a convergence of past innovations and future possibilities. Representing a blend of experience and expertise, it stands as a trusted component within countless systems worldwide. Its ongoing development and application reinforce its status as an essential asset in fluid management, promising continued relevance and reliability in an ever-evolving industrial landscape.

Share

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024