10 月 . 13, 2024 19:30 Back to list

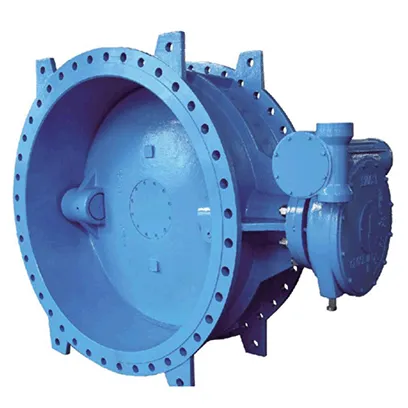

Durable Stainless Steel Butterfly Valve for Efficient Flow Control in Various Applications

Understanding Stainless Steel Butterfly Valves A Comprehensive Guide

Butterfly valves are an essential component in many fluid control systems across various industries. Among the different types of materials used to manufacture these valves, stainless steel has gained significant popularity due to its impressive properties. This article examines the features, benefits, applications, and maintenance of stainless steel butterfly valves.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn valve that uses a rotating disc to regulate or isolate the flow of fluid through a pipeline. The disc is mounted on a shaft and, when turned, the disc rotates perpendicular to the flow, allowing for quick opening and closing. This design makes butterfly valves an efficient choice for applications requiring rapid flow regulation.

Benefits of Stainless Steel Butterfly Valves

1. Corrosion Resistance One of the most significant advantages of stainless steel is its resistance to corrosion. This is particularly relevant in industries where valves are exposed to harsh chemicals or high humidity levels. Stainless steel butterfly valves can withstand corrosive environments, ensuring longevity and reducing replacement costs.

2. Durability Stainless steel is known for its strength and durability, making it suitable for demanding applications. Unlike other materials, stainless steel does not easily deform or suffer structural damage, ensuring that the valve maintains its integrity over time.

3. Temperature Tolerance Stainless steel can withstand both high and low temperatures, making these valves versatile for various applications. They are particularly useful in industries such as oil and gas, where extreme temperatures are common.

4. Low Maintenance The robustness of stainless steel can translate into lower maintenance requirements. Fewer repairs and replacements lead to reduced overall operational costs, making stainless steel butterfly valves a cost-effective solution.

5. Cleanliness and Hygiene Stainless steel is non-porous and easy to clean, making it an excellent choice for food, pharmaceutical, and semiconductor industries where hygiene is critical. The material does not harbor bacteria, ensuring that the fluid transported is clean and safe.

Applications of Stainless Steel Butterfly Valves

stainless steel butterfly valve

Stainless steel butterfly valves are widely employed across various sectors, including

- Water and Wastewater Treatment They are used for controlling flow in treatment plants, contributing to efficient water management. - Food and Beverage Industry These valves are essential in processing and packaging, where hygiene is paramount. - Chemical Processing The ability of stainless steel to resist corrosion makes it ideal for handling aggressive chemicals. - Power Generation In power plants, butterfly valves manage steam and water flow effectively, ensuring operational efficiency. - HVAC Systems They are often used in heating, ventilation, and air conditioning systems to regulate air flow effectively.

Maintenance Tips for Stainless Steel Butterfly Valves

To ensure the longevity and efficient operation of stainless steel butterfly valves, it's crucial to perform regular maintenance. Here are some essential maintenance tips

1. Regular Inspections Conduct routine inspections for any signs of wear or damage to the valve body, seat, or disc.

2. Lubrication Proper lubrication of the valve shaft is essential to prevent excessive wear and ensure smooth operation. Check manufacturer guidelines for specific lubricants.

3. Cleanliness Keep the valve and surrounding areas clean to prevent contamination and operational issues.

4. Check Seals Regularly inspect seals for wear and replace them as necessary to maintain a tight seal and prevent leaks.

5. Operational Tests Regularly test the valve operation to ensure it opens and closes smoothly without sticking or binding.

Conclusion

Stainless steel butterfly valves are an integral component of fluid control systems in a myriad of applications. Their corrosion resistance, durability, and low maintenance make them a preferred choice across various industries. By understanding their features, benefits, and maintenance requirements, businesses can make informed decisions in selecting the appropriate valves for their systems, ensuring efficiency and reliability in operations. As industries evolve and new materials and technologies emerge, stainless steel butterfly valves will continue to play a vital role in fluid management solutions.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024